Designing complex parts but struggling with traditional manufacturing limits? Achieving precision and efficiency can be tough, impacting your project timelines and final part quality. CNC milling solves this with computer-guided perfection.

CNC milling uses rotating tools controlled by computers to cut material away. It creates precise parts from metals or plastics based on digital designs. This method delivers unmatched accuracy for complex shapes and tight tolerances every time. It's key for accuracy, complex shapes, and reliable production.

Sticking with manual machining causes errors. CNC milling removes human guesswork. Let me show you exactly how this transforms part quality.

What is meant by CNC milling?

Ever struggled with inconsistent cuts? Hand-operated machines frustrate engineers daily. CNC milling ends that pain.

CNC milling means Computer Numerical Control milling. Computers direct cutting tools using G-code instructions from CAD files. This automates part creation with extreme repeatability across metals, plastics, or composites.

Core Mechanics Explained

Three elements make CNC milling unbeatable for precision:

| Component | Function | Impact on Quality |

|---|---|---|

| Cutting Tool | Spinning endmill removes material | Determines finish and detail level |

| Computer Control | Executes G-code from CAD/CAM | Eliminates human error |

| Worktable | Holds material, moves on X/Y/Z axes | Enables complex 3D shapes |

The spindle rotates tools up to 30,000 RPM while the worktable positions material. I program toolpaths in CAM software to optimize every cut. This synergy achieves ±0.001 inch tolerances consistently. For aerospace clients, we machine titanium brackets this way daily.

Why Material Choice Matters

Not all metals behave alike during milling. Aluminum cuts smoothly but steels require slower speeds. Exotic alloys like Inconel need specialized tool coatings. I learned this early when a stainless steel job ruined three endmills. Now we match tools to materials rigorously.

What is the process of CNC milling?

Waiting weeks for prototype revisions kills projects. Traditional methods drag timelines. CNC milling streamlines production.

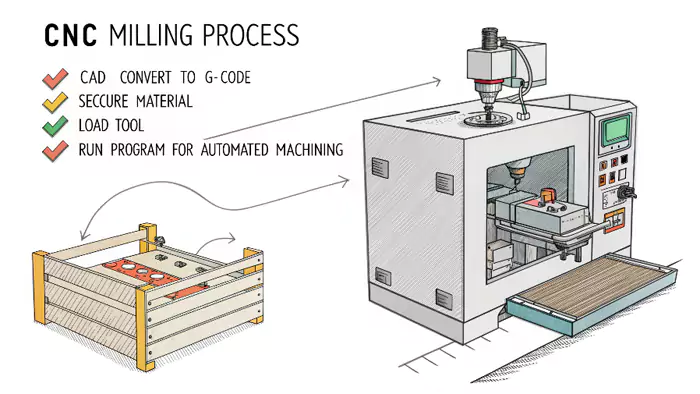

The CNC milling process starts with a 3D CAD model converted to machine instructions (G-code). Operators then secure material, load tools, and run the program. The machine follows exact paths to cut the final part automatically.

Breaking Down Each Phase

-

Design Phase

Engineers create CAD models1. I review these for manufacturability—adding fillets or adjusting wall thicknesses. One medical device design had impossible internal corners. We redesigned it together in 2 hours. -

Programming Phase

CAM software generates toolpaths. I simulate these to prevent collisions. Parameters like feed rate and spindle speed get tuned here. For 6061 aluminum, we use 18,000 RPM and 200 IPM feed rates typically. -

Setup Phase

Material gets clamped to the bed. Tools load into the carousel. We probe the workpiece to set coordinates. A robotic arm2 automates this at our Detroit facility, cutting setup time by 70%. -

Milling Phase

The machine executes the program. Coolant prevents overheating. Sensors detect tool wear mid-job. Last month, this saved a 500-unit titanium order when a drill bit chipped. -

Inspection Phase

Finished parts get measured with CMMs. We check critical dimensions against the CAD model. Statistical process control charts3 track deviations over time.

What is the difference between CNC cutting and milling?

Choosing the wrong method wastes time and money. Laser cutting seems similar but has critical limitations.

CNC cutting slices through flat sheets in straight lines using lasers or plasma. CNC milling removes material volumetrically with rotating tools. Milling creates 3D shapes; cutting makes 2D profiles.

When to Use Each Method

| Scenario | CNC Cutting | CNC Milling |

|---|---|---|

| Sheet metal brackets | ✓ Fast, low cost | Possible but slower |

| Engine block prototype | ✗ Cannot add depth | ✓ Handles complexity |

| Aluminum enclosures | ✓ Clean edges | ✓ Adds threaded holes |

| Injection molds | ✗ Limited detail | ✓ Core cavities |

Milling builds functional parts needing strength or precision. Cutting suits decorative panels or simple brackets. For a robotics client, we milled motor mounts with integrated bearing seats—something cutting couldn’t achieve.

Cost and Time Comparisons

Cutting costs less for flat parts. Milling investments pay off for complex geometries. One hydraulic valve body took 8 hours to mill but would require 12 welded pieces if cut. Assembly time dropped 90%.

Where is CNC milling used?

Sourcing parts feels like a gamble. Will suppliers meet aerospace specs or medical cleanliness standards? CNC milling delivers where others fail.

CNC milling builds critical components across industries. Aerospace uses it for turbine blades, medical for implants, automotive for engines, and industrial automation for robotic arms. Any field needing precision metal parts relies on milling.

Industry-Specific Examples

-

Aerospace

Turbine blades require inconel milling with ±0.0005" tolerances. We machine these in climate-controlled rooms. Material traceability is mandatory here. Every cut gets logged. -

Medical

Hip implants start as titanium billets. Our 5-axis mills contour them to match patient scans. Surface finishes must prevent bacterial growth. We achieve Ra<8μin finishes routinely. -

Industrial Automation

Robotic joint housings need hardness and lightness. We mill 7075-T6 aluminum with steel inserts. One client’s cycle time dropped 15% after we optimized their arm design for milling. -

Energy

Wind turbine gearboxes demand durable housings. We mill ductile iron castings weighing 800+ lbs. Rigid machine foundations prevent vibration during heavy cuts.

How Does CNC Milling Help You Get Great Parts?

Prototypes failing tolerance checks derail projects. CNC milling prevents this through controlled precision.

CNC milling achieves tight tolerances, complex geometries, and repeatable quality unattainable manually. It handles diverse materials while reducing waste and speeding production. This ensures parts perform reliably in critical applications.

Solving Common Pain Points

David faces four core challenges:

1. Tolerance Compliance

Our CNC mills hold ±0.001" routinely. For a surgical robot project, we hit ±0.0003" using temperature-compensated machines. Real-time tool wear sensors adjust paths automatically.

2. Rapid Quoting

Upload your CAD file to our portal. Algorithms analyze geometry and materials. Quotes return in 2 hours max. One automation designer got 27 variants quoted same-day for DFM feedback.

3. Quality Assurance

Every tenth part undergoes CMM checks. We email inspection reports with deviations highlighted. Statistical process control charts come standard for production runs.

4. Confidentiality Protection

NDAs precede file access. Encrypted servers store designs. Mill operators see only toolpaths—not full assemblies. Client IP stays secure always.

CNC Machining at Allied Metal | Small and Large Batch Manufacturing and Rapid Prototyping

Finding one shop for prototypes and production is tough. Most specialize in one or the other. We bridge both worlds.

Allied Metal handles everything: 1-piece prototypes to 10,000-unit runs. Our ISO 9001-certified facility combines 5-axis milling, EDM, and CMMs under one roof. Fast turnarounds meet aggressive deadlines without compromising precision.

Prototyping Like Production

-

Speed

Prototypes ship in 3 days using dedicated rush lines. One client tested 15 iterations in 4 weeks. Their product launched 3 months early. -

Cost Control

We use prototype runs to optimize production toolpaths. One gear housing’s machining time dropped 40% after refining feeds during prototyping. -

Material Consistency

Prototypes and production use identical metals from the same suppliers. No requalification needed when scaling up.

Production Excellence

| Batch Size | Our Approach | Client Benefit |

|---|---|---|

| 1-50 | High-mix cells | No minimum order quantity |

| 51-500 | Dedicated machines | 30% faster than job shops |

| 500+ | Automated pallet systems | 24/7 unmanned production |

Conclusion

CNC milling transforms digital designs into precise physical parts. It enables innovation across industries while ensuring reliability and efficiency from prototype to production.

-

Understanding CAD models is crucial for grasping how designs are created and modified in engineering, enhancing your knowledge of the design process. ↩

-

Learning about robotic arms in manufacturing reveals how automation improves efficiency and accuracy, key factors in modern production environments. ↩

-

Explore how SPC charts can enhance your manufacturing processes by tracking quality and reducing defects over time. ↩