Ⅰ. What are the motorcycle parts that can be customized by CNC machining?

CNC machining is now the center of attention in many industries due to its tremendous benefits. Currently, top companies in the motorcycle manufacturing industry use the process to create customized motorcycle parts such as motorcycle engine parts, wheels, bearings, and light parts.

Virtually all metal and plastic parts for motorcycles can be machined through CNC machining. Below, we will discuss some machined motorcycle parts.

1. Motorcycle wheels

Unlike cars, motorcycle wheels tend to be more noticeable. Therefore, properly customizing these wheels will improve the aesthetics of your bike. After all, aesthetics are more than just something that catches the eye easily.

2.Motorcycle parts machining

Discs happen to be the target when it comes to customizing wheels. Most of them are made of aluminum. Aluminum is known for its excellent machinability. CNC milling operations are used to customize wheels.

Tires are another area that requires customization. Once you get customized wheel discs, it makes sense to choose tires with great designs.

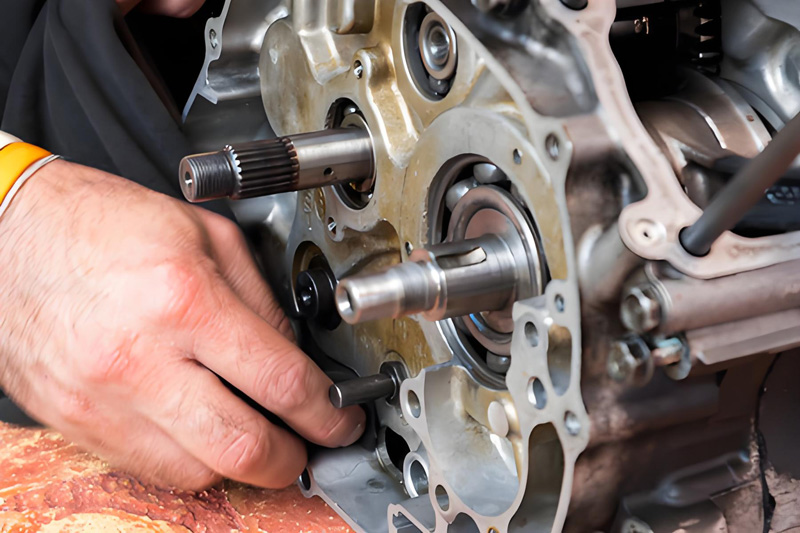

3. Engine parts

The engine of a vehicle (motorcycle) is the most critical component. Some refer to it as the heart of the vehicle. However, camshafts, cylinder heads and pistons are often complex and require high precision.CNC turning is the technology of choice for designing motorcycle engine parts.

4.CNC machining engine parts

a.Cylinder head

The cylinder head is usually made of aluminum, which controls fuel combustion by regulating the fuel-air mixture. In addition, the mixture passes through the combustion chamber at a specific angle. Sharper angles result in more fuel combustion, which increases the propulsion of the motorcycle. We won’t let you get tired of these mechanisms. The cylinder head is an important part of the motorcycle. The valves in the cylinder head that help regulate fuel intake are CNC machined products.

b. Camshaft

Camshafts control the engine cycle. They are made of CNC turned parts with different angles. The shafts in the engine rotate, causing the cams to open the fuel intake and exhaust valves. However, these shafts can be modified to allow for increased cam opening times. As a result, more fuel is burned to produce more electricity.

c. Pistons

The above modifications ensure that the work load on the piston is increased. Therefore, CNC customized pistons also become vital to withstand the pressure and temperature caused by other engine part modifications.

5. Motorcycle Lights

Lights are another complex part of customization. However, you need to use high-quality products because apart from being aesthetically pleasing, these lights are vital for the safety of riders and other road users, especially in the dark. Motorcycle lights consist of a light source (mainly a bulb), a lens and a cover. Notably, the lens and cover are the parts we focus on customizing.

The lenses are metal – usually made of aluminum alloy. A milling operation with a perfect finish will give the lens a shiny, almost mirror-like appearance. The cover, however, is made of tough plastic, which can also be machined to present a delicate shape.

A CNC machine is ideal for working with such materials, and common processes suitable include turning, milling, and cutting.

Allied Metal has CNC machining centers, CNC five-axis linkage machining centers, CNC lathes and a series of advanced processing equipment and has a wealth of processing technology and operational experience, if you have motorcycle parts need to be customized, please contact us directly.

Ⅱ. What surface finishes are available for machined motorcycle parts?

After production, CNC Services uses a variety of post-treatment processes to improve the functionality and aesthetics of CNC motorcycle parts, which we call surface treatments.

Post-processing operations are not required. However, they can be the difference between a good product and a bad one. Here are a few post-processing operations that most people use to help improve motorcycle manufacturing parts.

1. Pretreatment

Pretreatment is the first step of surface treatment, which mainly includes cleaning and descaling. The fittings may be contaminated with oil, dust and other impurities during the production process, which need to be cleaned by chemical or physical methods. At the same time, metal fittings may have rust, which needs to be removed using acid washing or mechanical grinding to ensure the effect of subsequent treatment.

2. Phosphating treatment

Phosphating treatment is a common surface treatment, which can improve the adhesion and corrosion resistance of the metal surface. By immersing the fittings in a solution containing phosphate, a phosphate film is formed on the surface, which can increase the adhesion of paint or other coatings.

3. Paint treatment

Painting is an important part of the surface treatment of motorcycle fittings, which can enhance the aesthetic appearance and protective performance of the fittings. It usually includes two steps: primer and top coat. The primer mainly plays the role of rust prevention and adhesion enhancement, while the top coat determines the color and luster of the accessory. After painting, the fittings need to be baked in a specific environment to ensure the curing of the paint film.

4. Electroplating

For accessories that need to enhance corrosion and abrasion resistance, such as handlebars, brake pedals, etc., they are usually plated. Electroplating utilizes the principle of electrolysis to deposit a layer of metal or alloy, such as chrome-nickel, on the surface of the accessory in order to improve its surface hardness and corrosion resistance.

5. Polishing and buffing

The final step is polishing and buffing, which is done to enhance the surface finish and texture of the fittings. The surface burrs and unevenness are removed by mechanical or chemical methods to make the surface of the fittings smooth and bright.

These are the typical surface treatment processes for motorcycle accessories, each step of which is designed to enhance the performance and appearance of the accessory so that it better serves the overall performance and aesthetics of the motorcycle. However, the specific process flow may vary depending on the material and application of the accessory, as well as the technical requirements of the manufacturer.

If you have any questions about motorcycle accessory manufacturing, please contact Allied Metal directly.

Ⅲ. What are the advantages of CNC machining motorcycle parts?

Currently, CNC machining services are the focus of many bike and motorcycle manufacturing companies that make CNC motorcycle parts.CNC services use machines to make a variety of custom motorcycle parts. So why use CNC machining for motorcycle parts?

The following are the advantages of CNC machining motorcycle parts:

1. High precision

CNC machining using computer control of the movement of the tool and workpiece, can achieve high precision machining, to meet the demand for high-precision parts manufacturing, precision can reach micron level.

2. High accuracy

CNC machine tools are controlled by computers with less human influence. Therefore, the human error is reduced and the accuracy is higher, so that the parts products processed by CNC have a higher degree of similarity with the original design.

3. Repeatability

Motorcycle manufacturers can produce customized parts with 100% similarity through CNC machining.

4. Flexibility

CNC machining allows for quick modification and adjustment of parts according to design requirements to accommodate different production needs.

5. Cost Savings

Manufacturing with CNC is cost-effective because it requires less labor time, and CNC machines also save on raw material costs.

6. High productivity

CNC machining is characterized by a high degree of automation and integration, which can significantly increase productivity, greatly reduce production cycle time and lower labor costs.

Ⅳ. Conclusion:

CNC machining technology plays an indispensable role in modern manufacturing industry with its high precision and diverse machining methods. It is also important to understand the importance of CNC machines as well as post-processing in the manufacturing of motorcycle parts.

Allied Metal are experts in manufacturing high quality customized motorcycle parts. If you have any requirements, please feel free to send us the design of the desired part. Our engineers will do their best to bring your design to life.