Updated December 12, 2025, by Lucy

Many engineers face CNC machining problems that slow projects, raise costs, and damage confidence in suppliers, and I want to help you avoid those failures.

Most CNC machining problems come from setup errors, tool issues, unstable materials, vibration, programming mistakes, tolerance drift, surface defects, and weak quality control, but each problem has clear and practical solutions.

I want you to keep reading because these problems appear in automotive, motorcycle, medical, and industrial equipment manufacturing every day, and I will show you the proven steps that I use to solve them in real production.

Common Setup and Tooling Problems?

I see many machining failures begin with early setup mistakes or tool misuse, and these problems usually grow worse during production.

Most setup and tooling issues come from unstable clamping, wrong tools, wrong parameters, or poor coolant flow, and you can fix them with better fixturing, correct tool choice, and stable chip control.

Workpiece Positioning and Clamping Errors

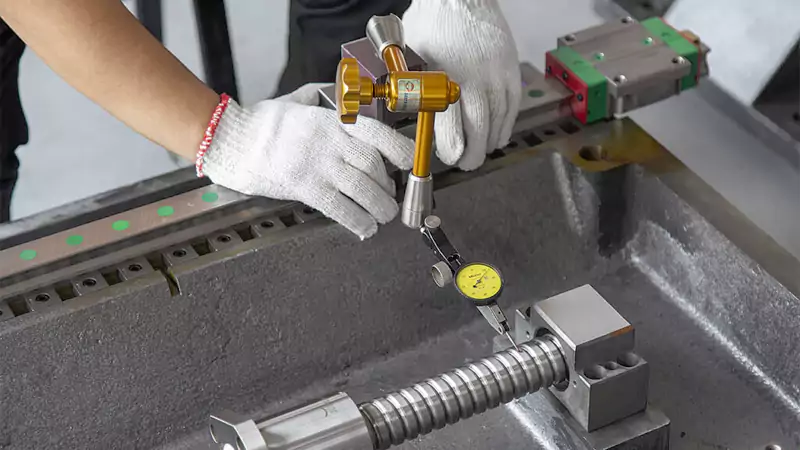

I always check clamping first because even a 0.01 mm shift during machining can ruin an entire batch. I make sure the part sits flat on the locating surfaces because chips or dust change the angle and cause taper or uneven depth. I confirm the clamping force1 because soft materials like aluminum distort under pressure, while harder materials like steel need stronger support. Long or thin parts require additional supports like tailstocks or soft jaws to keep the part stable. When clamping is wrong, I see vibration, tool wear2, poor surface finish, and wrong tolerances. When clamping is correct, the process becomes smooth and predictable.

Tool Selection, Wear, and Cutting Parameters

I see tool wear problems when shops push feed rates too high or use tools that do not match the material. I choose tools based on coating, sharpness, and length. Short tools reduce vibration. Long tools increase chatter. Stainless steel needs coated carbide. Aluminum needs sharp, uncoated or DLC-coated cutters. Titanium needs slow feeds and rigid setups. When tool wear grows, I see poor surface finish, dimensional drift, and burning marks.

Case Study: Stainless Steel Manifold Block

A customer from Germany needed SUS304 manifold blocks with strict hole tolerances.

| Parameter | Value |

|---|---|

| Material | SUS304 |

| Depth of Cut | 0.6 mm |

| Initial Feed Rate | 550 mm/min |

| Corrected Feed Rate | 360 mm/min |

| Final Roughness | Ra 0.8 μm |

| Tolerance | ±0.015 mm |

| Batch | 200 pcs |

The original feed caused micro-chatter. I shortened the tool length and slowed the feed. This simple change made the entire batch pass inspection.

Coolant, Lubrication, and Chip Removal Problems

Coolant and chip issues often cause heat buildup, spindle load spikes, and broken tools. I check coolant mix weekly because too much water reduces cooling and too much oil creates sticky chips. Stainless steel and titanium need high-pressure coolant3. Brass needs strong chip flushing. Aluminum needs clean coolant to prevent stains. Chip breakers help control chip size. Long chips wrap around tools and cause breakage. Short, clean chips improve accuracy and tool life.

Material, Vibration, and Machining Stability Issues?

I see many engineers choose good designs but run into problems because the material moves or the machine vibrates.

Material issues, machine vibration, and thermal deformation come from internal stress, hardness variation, long tools, weak rigidity, and heat expansion, and you can control these issues with better setups and controlled machining conditions.

%[Resolving Common Issues in CNC Machining](Resolving Common Issues in CNC Machining "Addressing processing issues")

Material-Related Problems During Machining

Every material reacts differently during cutting. Aluminum cuts fast but warps if the walls are thin. Stainless steel builds heat and shifts under heavy loads. Brass machines cleanly but needs sharp edges to avoid burrs. Plastics like POM expand with heat and shrink when cool. I check the material certificate4 before machining because wrong grades cause inconsistent tolerances. For materials with internal stress, I rough cut first, let the part cool, then finish. This prevents warping on shafts, plates, and medical components.

Machine Vibration, Rigidity, and Thermal Movement

A CNC machine5 produces accurate parts only when the setup is rigid. I reduce tool overhang because a long tool increases vibration. I check spindle bearings because worn bearings cause micro-vibration. Machines warm up during the first hour and change size by a few microns, so I warm up the machine before precision work. Thin walls and long parts need special support. Lower spindle speeds and reduced step-over help with precision finishing. These steps stabilize dimensions and prevent chatter marks.

Programming, Accuracy, and Tolerance Problems?

I have seen perfect CAM models turn into scrap because of one small programming mistake or poor tolerance control.

Programming errors, tolerance drift, and surface finish defects come from incorrect coordinates, tool offsets, heat, and vibration, and careful simulation and process control prevent these failures.

Programming and G-Code Mistakes

I always run a dry simulation because even a small digit error in a coordinate can destroy a part. Wrong tool numbers, wrong Z-height, or wrong origin cause the machine to cut air or crash. CAM paths also fail when the model is not clean or when the programmer chooses aggressive toolpaths without testing. Long programs need clear naming and step-by-step checks. These steps save time and prevent scrap, especially on expensive materials.

Dimensional Accuracy and Tolerance Drift

I use roughing and finishing passes because roughing removes stress and finishing corrects the final geometry. I measure early parts because tool wear affects size. Heat makes parts expand, so I cool aluminum parts before final measurement. Tight bores need fine finishing with boring bars or reamers. Insert wear on turning jobs also changes the final diameter. When the tolerance is ±0.01 mm, I always do a test cut and adjust tool offsets until the size stabilizes.

Surface Finish Problems and Their Solutions

Surface finish depends on sharp tools, stable conditions, and clean coolant. A dull tool drags metal and leaves visible lines. High feed rates create rough textures. I use climb milling for smoother results. Stainless steel requires strong coolant to avoid heat lines. Aluminum needs sharp cutters to prevent built-up edges. Thin walls chatter and produce waves. Long holes require controlled depth cuts and clean lubrication. A light finishing pass of 0.1 mm often produces a mirror-like finish.

Quality Control and Outsourcing Issues?

I see many buyers receive inconsistent parts because the supplier lacked proper inspection tools or stable QC methods.

Most quality and outsourcing issues come from weak inspection, inconsistent processes, and poor communication, and choosing a supplier with strong QC and machining experience prevents these risks.

Quality Control and Inspection Problems

I match every feature with the correct measuring tool. Micrometers for outer diameters. Bore gauges for holes. Thread gauges for all thread types. CMM for complex geometry. I check first article samples carefully and store measurement data for traceability. In batch production, I check pieces at set intervals because tool wear changes the size. This method builds consistency and prevents assembly issues in automotive and medical parts.

How to Minimize CNC Problems When Outsourcing

I always tell engineers to ask three simple questions when choosing a supplier.

First, ask what inspection equipment they use.

Second, ask for sample reports to understand their workflow.

Third, ask for machining suggestions because experienced machinists see risks before production.

Early communication prevents design mistakes. When I work with EU customers, I ask about load, environment, and assembly of the part. This helps me recommend better materials, fillets, and machining methods. A good supplier saves money and protects schedules.

Conclusion

CNC machining problems are common, but you can solve them with better setups, tools, materials, programming, and strong quality control.

-

Understanding clamping force is crucial for achieving precision in machining, ensuring quality and reducing errors. ↩

-

Exploring tool wear can help you optimize tool selection and improve machining efficiency, leading to better results. ↩

-

Understanding high-pressure coolant can enhance your machining efficiency and tool longevity. ↩

-

Understanding material certificates is crucial for ensuring the right material grades, which directly affect machining accuracy and tolerances. ↩

-

Exploring Milling Operations and Machine Tool Varieties. ↩

Thanks for the article https://l-spb.ru/