Many engineers see tin listed on drawings, but few truly understand its limits in real production. I have seen wrong material choices cause deformation, wear, and early failure.

Tin metal is a soft, corrosion-resistant metal mainly used for coatings, soldering, and specific functional parts, rather than as a primary structural material in CNC machining.

I have worked with tin and tin-related materials during more than twenty years of CNC machining. In most cases, tin appears as a coating, an alloy element, or a functional layer. When buyers understand what tin can and cannot do, material selection becomes much safer and more efficient.

What Is Tin Metal in Engineering Terms?

Tin is often misunderstood because it looks metallic but behaves very differently from common CNC materials.

Tin is a low-melting, non-ferrous metal with high corrosion resistance and very low mechanical strength, which limits its use in load-bearing components.

From an engineering view, tin is defined by softness and stability rather than strength. Pure tin deforms easily under load. This makes it unsuitable for shafts, frames, or brackets. However, its chemical stability1 makes it valuable in controlled environments.

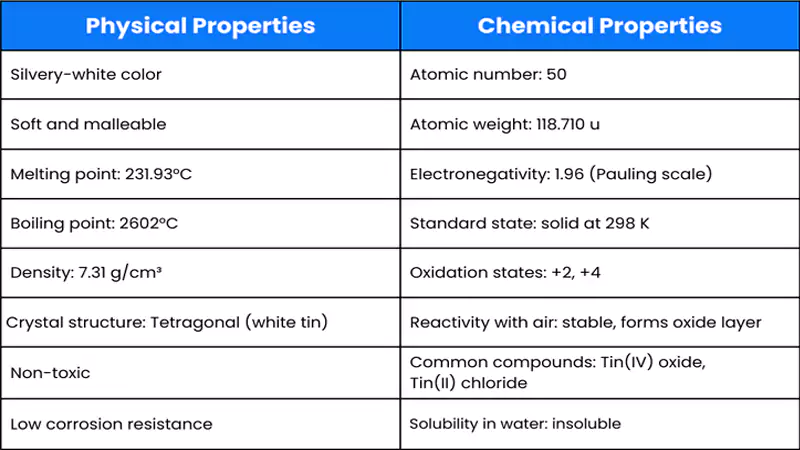

Basic Characteristics of Tin

| Property | Typical Value |

|---|---|

| Density | ~7.3 g/cm³ |

| Melting point | ~232°C |

| Tensile strength | Very low |

| Corrosion resistance | High |

| Electrical behavior | Good conductivity |

I always explain to clients that tin is rarely selected for strength. It is selected for protection, conductivity, or compatibility with other metals.

Key Properties of Tin Metal?

Material properties decide how a metal behaves during machining and service. Tin behaves very differently from aluminum or steel.

Tin metal is soft, ductile, and easy to deform, which makes it unsuitable for precision load-bearing CNC parts but useful for surface-related functions.

Tin cuts easily, but that is not an advantage in most CNC work. Chips smear. Edges collapse. Dimensional stability is poor. During my early years, I tested tin blocks on CNC lathes. The parts lost shape during clamping.

Property Impact in Manufacturing

| Property | Manufacturing Impact |

|---|---|

| Softness | Poor dimensional control |

| Low strength | Not suitable for structure |

| Corrosion resistance | Good for coatings |

| Low melting point | Sensitive to heat |

These properties explain why tin appears more often as a coating or alloy element rather than as a machined solid part.

Tin vs. Other Common Metals in Manufacturing?

Material comparison helps buyers avoid wrong assumptions. Tin is often confused with aluminum or copper.

Tin differs greatly from aluminum, copper, and steel in strength, stiffness, and machinability, which limits its direct use in CNC machining.

Comparison Table

| Metal | Strength | Machinability | Typical Use |

|---|---|---|---|

| Tin | Very low | Poor stability | Coatings, solder |

| Aluminum | Medium | Excellent | Structural parts |

| Copper | Medium | Fair | Conductive parts |

| Steel | High | Good | Load-bearing parts |

When a buyer asks if tin can replace aluminum, my answer is always no. The two metals serve very different roles.

Common Applications of Tin in Modern Industries?

Although tin is not a structural metal, it plays an important role in many industries.

Tin is widely used in electronics, medical devices, aerospace electronics, and consumer products as coatings, solders, and alloy components.

In automotive and aerospace sectors, tin often appears as a surface layer on connectors or bearings. In medical devices, tin coatings2 help improve corrosion resistance and compatibility.

Typical Applications

- Tin plating for corrosion protection

- Tin-based solder in electronics

- Tin alloys such as bronze

- Low-friction surface layers

These uses rely on tin’s surface behavior, not its strength.

Is Tin Suitable for CNC Machining and Custom Parts?

This is the question I receive most often from buyers.

Pure tin is generally not suitable for CNC machining of custom parts due to its softness and instability, but tin alloys and coatings are widely used.

Case Study: Tin-Plated Precision Connector Pin

| Parameter | Value |

|---|---|

| Base material | Copper alloy |

| Coating | Tin plating3 |

| Thickness | 8–12 µm |

| Machining process | CNC turning |

| Function | Electrical contact |

| Result | Stable conductivity and corrosion resistance |

In this project, tin was never machined directly. It was applied after machining. This is the correct approach in most cases.

Design and Manufacturing Considerations When Using Tin?

Correct use of tin requires planning.

Tin should be treated as a functional surface or alloy element, not as a primary CNC material for load-bearing components.

Practical Guidelines I Follow

| Guideline | Reason |

|---|---|

| Avoid machining pure tin | Poor stability |

| Use tin as coating | Best performance |

| Select proper base metal | Strength control |

| Control heat | Prevent deformation |

When buyers involve CNC suppliers early, material misuse can be avoided. This saves cost and prevents redesign.

Conclusion

Tin metal plays a valuable but limited role in manufacturing. When used correctly as a coating or alloy element, it supports performance without risking structural failure.

-

Understanding chemical stability helps in selecting materials for specific environments, ensuring durability and performance. ↩

-

Understanding What Tin Plating Is, Its Benefits, Processes, Types, Suitable Materials, and Applications ↩

-

Explore the advantages of tin plating for enhancing conductivity and corrosion resistance in electrical components. ↩

999rgame is the new thing. The gameplay looks alright, I have not tested it myself, but you can check it out: 999rgame

Having a blast with fun88bong88! Great selection of games and always something new to try. The promotions are also a nice bonus. Check it out, you won’t regret it! fun88bong88

Having trouble with jiliwinapplogin? Double-check your details, fam! Once you’re in, it’s game on! Good luck! jiliwinapplogin

88clbapp… another app to try out. Easy to instal and start to play some games, hope it’s good like what I expected: 88clbapp