Getting a physical part fast is critical. Rapid prototyping solves this problem. It turns digital designs into real parts quickly. This speed helps test ideas and find problems early.

Rapid prototyping is a group of techniques to quickly create a physical part or assembly from a digital design. Its primary goal is to accelerate product development by allowing for immediate testing and iteration before full-scale production begins.

Moving from concept to physical part used to take weeks. Now, it can take just days. This guide will explain the different methods. We will look at how each one works and when to use them. This knowledge will help you choose the best path for your next project.

What is Rapid Prototyping?

You need to test a design, but how? Rapid prototyping builds parts layer by layer or by cutting material away. It is a fast way to make a real object from a 3D model. This process helps engineers and designers see their ideas in real life.

Rapid prototyping is the fast fabrication of a physical part, model, or assembly using 3D computer-aided design (CAD). It uses additive manufacturing (3D printing) or subtractive methods (like CNC machining) to create objects for design validation and functional testing.

Core Principles and Workflow

The process always starts with a 3D model1. This digital file is sliced into layers. The prototyping machine then reads this data. It builds the part one layer at a time or machines it from a solid block. The key is speed. The goal is to get a part in hand as fast as possible. This allows for quick feedback and design changes.

Evolution of Prototyping

Before these technologies, prototyping was slow. It involved manual crafting or expensive tooling. Rapid prototyping changed everything. It democratized manufacturing. Now, even small teams can create complex parts quickly. This has accelerated innovation across all industries.

Benefits of Rapid Prototyping in Manufacturing

Why spend time and money on prototypes? The benefits are clear and impactful. It is not an extra cost. It is an investment that saves money later. Catching a design flaw early prevents huge losses down the line.

Rapid prototyping offers significant advantages including faster time-to-market, reduced development costs, and improved product quality through early design validation and functional testing, ultimately de-risking the entire production process.

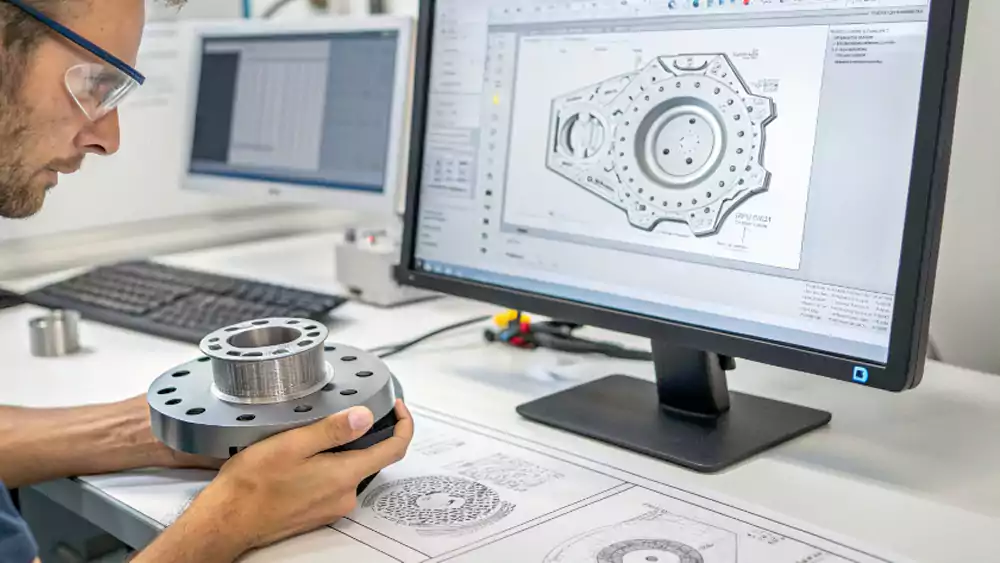

%[Metal parts for rapid prototyping and assembled prototype products on a table](https://cncmachiningsupplier.com/wp-content/uploads/2025/08/Benefits-of-Rapid-Prototyping-in-Manufacturing.webp “Advantages of rapid prototyping”)

Tangible Business Advantages

The main benefit is speed. You can iterate designs in days, not months. This gets products to market faster. It also saves money. Fixing a CAD file is cheap. Fixing a molding tool is very expensive. Prototyping finds these mistakes early.

| Benefit | Impact |

|---|---|

| Speed | Drastically shortens the design cycle. |

| Cost Saving | Identifies errors before mass production. |

| Improved Communication | Provides a tangible model for team and client feedback. |

| Customization | Allows for easy creation of bespoke designs. |

Enhancing Design and Collaboration

A picture on a screen is not enough. A physical model allows everyone to understand the design. Engineers, designers, and clients can all hold the part. This improves communication. It ensures everyone is on the same page before moving to production.

Types of Rapid Prototyping & Manufacturing Methods

Which process is right for your part? The answer depends on your needs. Each method has its own strengths. Some are great for looks. Others are perfect for strength. Choosing the right one is key to a successful prototype.

Several key methods exist for rapid prototyping, primarily categorized into additive (3D printing) and subtractive (CNC machining) processes, each suitable for different materials, tolerances, and application requirements.

3D Printing (Additive Manufacturing)

This method builds parts by adding material layer upon layer. It is ideal for complex geometries that are impossible to machine.

SLA (Stereolithography)2

SLA uses a laser to cure liquid resin into hardened plastic. It produces parts with very smooth surfaces and high detail. It is perfect for visual models and concept prototypes. However, the parts can be brittle and are not ideal for functional testing.

SLS (Selective Laser Sintering)

SLS uses a laser to fuse nylon powder particles. The surrounding powder supports the part during printing. This means no support structures are needed. SLS parts are strong and durable. They are good for functional testing and complex assemblies.

FDM (Fused Deposition Modeling)

FDM is the most common and affordable technology. It works by extruding a thermoplastic filament layer by layer. The parts are strong but often have visible layer lines. It is great for basic proof-of-concept models and quick checks.

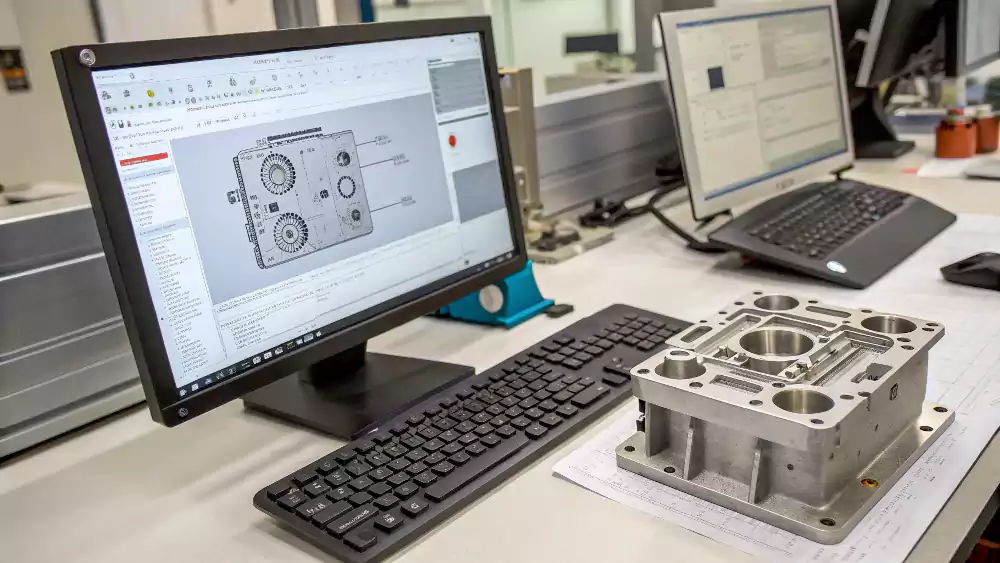

CNC machining for prototypes

CNC machining is a subtractive process. It starts with a solid block of material. A computer-controlled mill then cuts away material to form the part. It is excellent for parts that need high strength, tight tolerances, and real production materials like metals and engineering plastics.

Vacuum casting

This process uses a silicone mold created from a master pattern (often 3D printed). Polyurethane resin is then poured into the mold. It is perfect for creating 10-20 copies of a part in a flexible, rigid, or transparent material. It offers a good balance between quality and cost for small batches.

Sheet metal prototyping

This involves cutting, bending, and assembling sheet metal to create prototypes. It is the only method for parts that will be stamped or formed in production. It allows for testing the manufacturability of sheet metal designs.

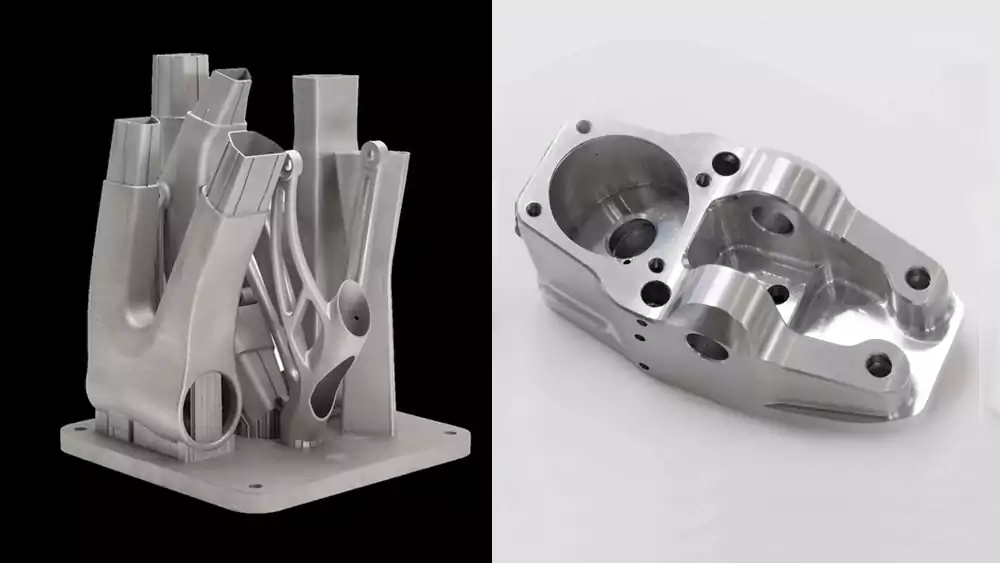

3D Printing vs CNC Machining: Which to Choose?

You need a prototype, but which method is best? The choice is not always simple. It depends on what you need the prototype to do. Is it for show or for go? Your answer will guide your decision.

Choose 3D printing for complex, lightweight geometries and fastest lead times when ultimate material strength isn't critical. Choose CNC machining for prototypes that require high precision, superior material properties, and must function identically to the final production part.

Breaking Down the Decision

Think about your priority. Is it speed, cost, strength, or accuracy? 3D printing wins on speed for complex shapes. CNC machining wins on strength and precision. For a visual model, 3D printing is often sufficient. For a part that must withstand stress and fit with other components, CNC is the reliable choice.

| Factor | 3D Printing | CNC Machining |

|---|---|---|

| Best For | Complex shapes, speed | Strength, precision, real materials |

| Materials | Plastics, resins | Metals, plastics, composites |

| Surface Finish | Layer lines (usually) | Machine smooth |

| Cost (Low Vol.) | Generally lower | Generally higher |

The Hybrid Approach

Sometimes the best solution uses both methods. You can 3D print the main body of a part for complexity. Then you can CNC machine a critical metal component for strength. This hybrid approach combines the benefits of both worlds.

Comparing Prototyping Processes (Table/Chart)

With so many options, how do you quickly compare them? A direct side-by-side comparison cuts through the noise. It provides a clear, at-a-glance view of which technology aligns with your project's specific needs.

This comparison chart provides a clear, concise overview of the key rapid prototyping methods, highlighting their ideal applications, material options, and relative strengths to guide your selection process efficiently.

%[Comparison of different rapid prototyping techniques](https://cncmachiningsupplier.com/wp-content/uploads/2025/08/Comparison-of-different-rapid-prototyping-techniques.webp “Comparison of rapid prototyping techniques”)

A Detailed Process Breakdown

The table below summarizes the core characteristics of each major prototyping method. Use it as a starting point to narrow down your choices based on what matters most for your prototype, whether it's material properties, cost, or speed.

| Process | Type | Best For | Materials | Tolerances | Lead Time |

|---|---|---|---|---|---|

| FDM | Additive | Basic models, proof-of-concept | Standard thermoplastics | ± 0.5% (lower limit ± 0.5 mm) | Very Fast |

| SLA | Additive | High-detail visual prototypes, molds | Photopolymer resins | ± 0.5% (lower limit ± 0.15 mm) | Fast |

| SLS | Additive | Functional prototypes, complex parts | Nylon powders | ± 0.3% (lower limit ± 0.3 mm) | Fast |

| CNC Machining | Subtractive | Functional parts, high precision | Metals, plastics, woods | ± 0.025 - 0.125 mm | Medium |

| Vacuum Casting | Forming | Small batches, flexible parts | Polyurethane resins | ± 0.2% (lower limit ± 0.15 mm) | Medium |

| Sheet Metal | Subtractive | Enclosures, brackets, housings | Sheet metal (steel, aluminum) | ± 0.1 - 0.5 mm | Medium |

Interpreting the Data for Your Project

This chart is a guide, not a strict rule. For instance, while CNC machining has a "medium" lead time, a simple part can be made very quickly. Conversely, a very large SLS part might take longer. Always consult with your manufacturing partner for the most accurate assessment for your specific project.

Applications of Rapid Prototyping Across Industries

Who uses these techniques? The answer is almost everyone. From medical to aerospace, rapid prototyping is a key tool. It drives innovation by allowing for faster iteration and testing.

Rapid prototyping is utilized across diverse sectors including automotive, aerospace, medical, and consumer goods for applications like concept modeling, functional testing, manufacturing tooling, and even creating end-use parts.

Automotive Industry

Car manufacturers use rapid prototyping extensively. They create functional engine components to test performance. One major German automaker used CNC machined aluminum parts to test a new transmission design. This allowed them to validate fit and function before ordering expensive production tooling. They saved months of development time and avoided costly design errors.

Medical Sector

The medical field relies on prototyping for patient-specific solutions. Surgeons use 3D printed models of patient anatomy to practice complex surgeries. A famous children's hospital creates exact replicas of children's hearts before surgery. This practice reduces operation time and improves surgical outcomes. Dental labs also use it to create precise crowns and bridges quickly.

Aerospace and Defense

Aerospace companies demand high precision and material performance. They use rapid prototyping for lightweight aircraft components. A leading aerospace company prototypes turbine blades using SLS printing. They test these parts in wind tunnels to validate aerodynamic performance. This process helps them innovate faster while maintaining strict safety standards.

Consumer Electronics

Electronics companies use prototyping to test form and function. They create housing prototypes for new smartphones and laptops. A well-known tech company uses vacuum casting to create 20-30 prototype units of a new device. These units are used for user testing and marketing photos long before mass production begins. This helps them gather feedback and make design improvements early.

In-house vs Outsourced Rapid Prototyping Services

Should you buy a machine or use a service? This is a common question for engineers. Both options have merits. The right choice depends on your volume, expertise, and needs.

Maintain in-house prototyping for maximum iteration speed and control over intellectual property on frequently used, less complex processes like FDM. Outsource to experts for accessing a wider range of technologies, higher-quality finishes, and specialized materials without capital investment.

Evaluating the Trade-offs

An in-house printer is great for quick, simple drafts. It keeps your work confidential. But it limits you to one technology. A professional service provider gives you access to industrial-grade machines3. They have experts who can advise on the best method and material for your project. They handle the maintenance and expertise burden for you.

How to Reduce the Cost of Rapid Prototyping?

Prototyping is an investment, but costs can add up. How can you keep them under control? Smart design choices and process decisions make a big difference. A little planning goes a long way.

To reduce rapid prototyping costs, optimize your design for the chosen manufacturing process (e.g., avoid unnecessary support structures in 3D printing), choose the appropriate material and technology for the prototype's purpose, and consider batch ordering to amortize setup fees.

Practical Cost-Saving Strategies

First, know what you need. Do you need a strong part or just a visual model? Using a premium material for a simple check is wasteful. Second, design for manufacturability4. Slightly rounding a sharp edge can drastically reduce CNC machining time. Third, work with your vendor. They can often suggest design tweaks that lower the cost without hurting the function.

Rapid Prototyping with Allied Metal

You need a partner you can trust. At Allied Metal, we live and breathe precision manufacturing. I started on the shop floor. I know what it takes to make a great part. We understand the pressure you are under to deliver.

At Allied Metal, we leverage our expertise in both CNC machining and 3D printing to provide tailored rapid prototyping solutions. We focus on delivering functional, high-precision prototypes in real materials, ensuring your design is validated for performance, not just appearance.

Our Approach to Your Success

We do not just make parts. We become an extension of your team. We look at your drawings with a critical eye. We suggest improvements for manufacturability. We help you choose the most efficient and cost-effective method. We get you the parts you need, when you need them, so you can meet your deadlines and push your projects forward.

Conclusion

Rapid prototyping is a powerful tool for innovation. Choosing the right method saves time and money while ensuring part quality.

-

Learn about the creation of 3D models and their importance in the prototyping process. ↩

-

Explore this link to understand how SLA technology can enhance your 3D printing projects with high detail and smooth surfaces. ↩

-

Learn about industrial-grade machines and how they can elevate your printing projects to a professional level. ↩

-

Understanding best practices in design for manufacturability can help you optimize production processes and reduce costs. ↩

Alright, ggpanaloapp.info is the place to be for games . I spent hours download lots of game and easily get to play them all. I am happy with the amount of content they provide! Definitely worth checking out! ggpanaloapp

Looking for a new place to place your bets? I tried 11ttbet. Seemed pretty standard, good odds maybe. Honestly, do your research before throwing down any cash, but here’s the link if you wanna peek: 11ttbet

Yo! Win999phcash is my go-to spot for quick wins. The site’s slick and easy to navigate. Definitely worth checking out if you’re looking for some fun. Check it out here: win999phcash.

Aaajili2, another one bites the dust… another winner I mean! Pretty standard site, but hey, if it pays out, I’m there! Give it a shot, maybe you’ll hit big: aaajili2.

Been playing on 7gamesbet1 for a bit now. Payouts are relatively quick and the customer support is responsive. Not bad at all! Give ’em a try! 7gamesbet1