Designing a part that needs strength and durability? Choosing the wrong steel can lead to difficult machining, rapid tool wear, and high costs, or even part failure in the field.

Choosing the right steel for CNC machining involves balancing the material’s mechanical properties (strength, hardness) with its machinability. The grade you select directly impacts the part’s performance, cost, and manufacturing time.

Throughout my career, I’ve machined all kinds of steel, and no two are the same. For engineers like David, who select materials for high-performance machinery, this matters. Each type of steel machine differently, affects tooling differently, and fits different uses. Choosing the right material is the foundation of any successful part. It’s more than just specs—it’s about machinability, tolerance, and how well the steel fits the final application. Keep reading to master CNC machining steel) selection.

What Is Steel?

We all know steel is strong, but what is it from a technical standpoint? What is this fundamental material that forms the backbone of modern industry?

Steel is an alloy of iron and carbon. The amount of carbon, typically below 2%, is the primary element that determines the steel’s hardness, strength, and other key mechanical properties.

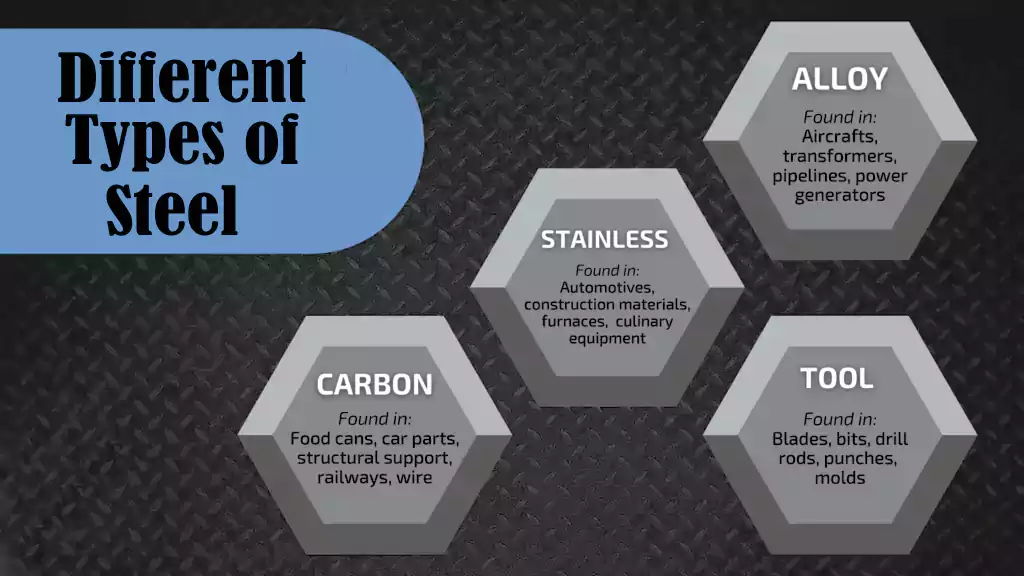

Types of steel and what they are made of

Steel is divided into different categories based on its carbon content and other alloying elements:

Carbon Steel

- Low Carbon Steel: Soft and easy to machine, but not very strong.

- Medium Carbon Steel: A balance between strength and machinability.

- High Carbon Steel: Hard and strong, but wears tools fast.

Alloy Steel

- Includes elements like chromium, molybdenum, and nickel.

- Offers improved strength, toughness, or resistance to wear and corrosion.

Stainless Steel

- Contains chromium (usually over 10%) for corrosion resistance.

- Tough to machine, but needed in many industrial applications.

I often compare these types by how they behave on the shop floor—some steels cut clean, others fight you all the way. That’s why understanding them matters.

What Is Machining Steel?

Now that we know the basics of steel, you might have seen the term ‘free-machining steel’ on a drawing. Is there a special type of steel made just for machining? What does it mean when a supplier refers to a specific grade as a "machining steel"?

Machining steel, often called free-machining steel, is a type of steel specifically formulated for excellent machinability. It contains additives like sulfur or lead that help break chips and reduce tool wear.

The Role of Free-Machining Steels in CNC Machining Steel

Not all steels are created equal when it comes to CNC machining. Some grades are tough and "gummy," causing long, stringy chips that are difficult to manage and lead to rapid tool wear. To solve this problem, steel manufacturers developed free-machining steels.

These are steel alloys that have had small amounts of specific elements added to them for the sole purpose of improving their performance in automated machining operations like those on a CNC lathe.

The most common additives are:

- Sulfur: This is the most common additive. Sulfur combines with manganese in the steel to form manganese sulfides. These act as microscopic discontinuities in the material. When a cutting tool hits one of these inclusions, the metal chip breaks off easily. Instead of long, dangerous strings, you get small, manageable chips that are easily flushed away by coolant.

- Lead: In grades like 12L14 steel1, a small amount of lead is added. The lead acts as an internal lubricant during the cut, which reduces friction between the tool and the workpiece. This results in less heat, lower tool wear, and a better surface finish.

- Bismuth and Tellurium: These are other elements that can be used to improve machinability in a similar way.

For a manufacturing partner, using a free-machining steel like 12L14 allows for much higher cutting speeds and feed rates. This translates directly into shorter cycle times and lower costs, which is a key priority for an engineer like David who is looking for cost-effective machining services. The trade-off is that these steels often have slightly lower ductility and are not as good for welding.

Why Is It Important to Choose the Right CNC Machining Steel?

With thousands of steel grades available, why is the selection process so critical? How does the choice of steel impact the part beyond just its strength?

Choosing the right steel is critical because it affects the part’s performance, lifespan, manufacturing cost, and lead time. The wrong choice can lead to premature failure or unnecessarily high production costs.

Choosing the Right CNC Machining Steel

From my experience running a machine shop, the choice of alloy is the single most important decision at the design stage. This choice has a ripple effect through the product’s lifecycle and the entire process of CNC machining steel. For an engineer like David, it’s a balancing act between performance and manufacturability.

Here’s why the decision is so critical:

-

Final Part Performance: This is the most obvious reason. CNC-machined steels must have the right mechanical properties—such as tensile strength, hardness, toughness, and wear resistance—to function correctly and safely in its final application. A gear made from soft steel will wear out quickly, while a bracket made from brittle steel could snap under load.

-

Machinability and Cost2: As we discussed, different steels machine differently.

- A difficult-to-machine steel (like stainless steel or a high-alloy tool steel) requires slower cutting speeds, more expensive cutting tools, and longer cycle times. This directly increases the cost of the part.

- An easy-to-machine steel allows for faster, more efficient production, which lowers the cost.

-

Post-Processing Requirements: The choice of steel determines what can be done to it after machining. Can it be easily welded? Can it be heat-treated to a specific hardness? Will it accept a certain type of coating, like chrome plating or black oxide?

-

Corrosion Resistance: For parts that will be exposed to moisture or other corrosive elements, choosing a material like stainless steel is essential to prevent rust and ensure a long service life.

-

Tolerance Control: Softer, "gummier" steels can be more difficult to hold tight tolerances on, while a stable, well-chosen alloy steel will machine cleanly and predictably.

This is why we often provide Design for Manufacturability (DFM) feedback at Allied Metal. Collaborating with an engineer on the material choice can often lead to a part that is just as strong but much more cost-effective to produce.

What Are the Four Main Types of Steel?

How are the thousands of different steel alloys organized? What are the main families or types of steel that are used in manufacturing?

The four main types of steel are carbon steel, alloy steel, stainless steel, and tool steel. Each category is defined by its chemical composition and has distinct mechanical properties.

Diving Deeper into Steel Categories

To make sense of the vast world of steel, metallurgists group them into four primary families. For an engineer like David, knowing these basic categories is the first step in narrowing down the choices for a specific application.

1. Carbon Steel

- Composition: This is the largest group. Its properties are mainly defined by its carbon content. It contains only trace amounts of other alloying elements. It is further broken down into low-carbon (mild steel)3, medium-carbon, and high-carbon steel.

- Characteristics: Strong, durable, and relatively inexpensive. It is prone to rust if not coated.

- Use: The most common type of steel, used for everything from structural beams and car bodies to machine parts and fasteners.

2. Alloy Steel

- Composition: This is carbon steel that has had other alloying elements (like manganese, nickel, chromium, molybdenum, or silicon) intentionally added to improve its properties.

- Characteristics: These additions can be used to increase hardness, strength, toughness, wear resistance, and its ability to be heat-treated (hardenability).

- Use: Used for high-strength applications like gears, shafts, axles, and machine tool components. 4140 steel is a classic example.

3. Stainless Steel

- Composition: The defining characteristic of stainless steel is its high chromium content, typically a minimum of 10.5%. The chromium creates a passive oxide layer on the surface.

- Characteristics: Its main property is excellent corrosion resistance. It is also known for its clean appearance and good strength.

- Use: Used in food processing, medical equipment, marine hardware, and anywhere that resistance to rust and corrosion is critical. 304 and 316 are very common grades.

4. Tool Steel

- Composition: These are very high-carbon alloy steels containing elements like tungsten, molybdenum, and vanadium.

- Characteristics: They are extremely hard, abrasion-resistant, and able to hold a sharp cutting edge, even at high temperatures.

- Use: As the name implies, they are used to make manufacturing tools, such as drill bits, end mills, molds, and dies for cutting and forming other metals.

How Do the Different Types of Steel Compare?

Understanding these four main categories is helpful, but for an engineer, the key is to compare them side-by-side to make a practical choice. For a practical application, how do these four types of steel stack up against each other? What are their key differences in terms of cost, machinability, and performance?

Carbon steel is cheap and versatile. Alloy steel offers higher strength. Stainless steel provides corrosion resistance. Tool steel delivers extreme hardness and wear resistance. Each has a specific purpose.

Diving Deeper into a Head-to-Head Comparison

For an engineer like David who needs to make a material choice, a direct comparison is often the most helpful tool. Here is a table that summarizes the key characteristics of the four main types of steel.

| Feature | Carbon Steel | Alloy Steel | Stainless Steel | Tool Steel |

|---|---|---|---|---|

| Primary Property | Versatility and low cost | High strength and toughness | Corrosion resistance | Extreme hardness and wear resistance |

| Corrosion Resistance | Poor (will rust easily if not coated) | Poor to Fair (better than carbon but still needs coating) | Excellent | Fair (can rust, but often better than alloy steels) |

| Machinability | Good to Excellent (especially low-carbon grades) | Fair to Good (generally harder than carbon steel) | Fair to Poor (can be "gummy" and work-harden) | Poor to Very Poor (extremely hard and abrasive to tools) |

| Weldability | Good to Excellent (low-carbon grades are best) | Fair to Poor (often requires special procedures) | Fair to Poor (can be tricky to weld properly) | Very Poor (not recommended for welding) |

| Cost | $ (Lowest) | $$ (Moderate) | $$$ (High) | $$$$ (Highest) |

| Common Grades | 1018, 1045, A36 | 4140, 4340 | 304, 316, 17-4 PH | A2, D2, O1, M2 |

| Typical Applications | Structural parts, machine frames, general-purpose components. | Gears, shafts, axles, high-strength fasteners. | Food processing equipment, medical devices, marine hardware. | Cutting tools, molds, dies, punches. |

This table shows the clear trade-offs. If the part doesn’t need to be exceptionally strong or corrosion-resistant, low-carbon steel is the most economical choice. If strength is the top priority, you move to an alloy steel. If it will be exposed to a corrosive environment, stainless steel is necessary. And if the part needs to be incredibly hard to cut other materials, you must use a tool steel.

Critical Selection Tips

- Machinability matters most for complex parts: 12L14 > 303 SS > 4140 > D2

- Pre-hardened steels4 (like 4140 HT) save time but accelerate tool wear

- Lead-added steels (12L14) improve chip breaking but contaminate some environments

When prototyping, start with free-machining variants5 like 303 stainless instead of 304. The slight property reduction rarely impacts function but dramatically eases machining. Document setup parameters for each material – they become your shop’s gold standard.

What Types of Steel Are Commonly Used in Precision CNC Machining?

Out of the thousands of grades, which specific types of steel do machine shops work with most often? What are the common, reliable choices for custom machined parts?

Commonly machined steels include 1018 and 1045 carbon steel, 4140 alloy steel, 304 and 316 stainless steel, and A2 and D2 tool steel. These grades offer a good balance of properties.

Diving Deeper into Common Steel Grades

In my shop, we see a wide variety of materials, but a few specific grades of steel appear on drawings time and time again. These are the workhorse materials that engineers like David frequently specify because they offer a known and reliable combination of performance and manufacturability.

Here are some of the most common types:

-

1018 Carbon Steel:

- This is a low-carbon steel that is one of the most common materials for general-purpose machined parts. It is relatively soft, easy to machine, and easy to weld. It’s used for things like mounting plates, brackets, and simple shafts.

-

1045 Carbon Steel:

- This is a medium-carbon steel. It is stronger and harder than 1018 and can be heat-treated to further increase its hardness. It’s used for parts that need a bit more strength, like bolts, studs, and simple gears.

-

- This is a very popular chromium-molybdenum alloy steel. It has excellent strength, toughness, and wear resistance. It responds very well to heat treatment. It is a go-to choice for high-strength machine components like axles, gears, and fixtures.

-

- These are the two most common grades of stainless steel. 304 is used for general-purpose corrosion resistance in applications like food processing equipment. 316 has added molybdenum, which gives it superior corrosion resistance, especially against chlorides, making it ideal for marine and chemical applications.

-

A2 & D2 Tool Steel:

- These are common "cold-work" tool steels. A2 is an air-hardening steel known for its good balance of toughness and wear resistance. D2 is a high-carbon, high-chromium steel that is more wear-resistant but less tough than A2. Both are used to make dies, punches, and other forming tools.

What Are the Common Steel Machining Processes?

How is a solid block of steel transformed into a precise component? What are the primary CNC machining processes used to cut and shape steel?

The common processes for machining steel are CNC milling for creating flat surfaces and pockets, CNC turning for cylindrical parts, drilling for holes, and grinding for achieving the tightest tolerances.

Diving Deeper into Steel Processing Methods

Machining steel is a core capability of any serious machine shop. Because steel is much harder and tougher than a material like aluminum, the processes must be robust and well-controlled.

Here are the common CNC machining processes we use for steel parts:

-

CNC Milling:

- Process: A rotating cutting tool (an end mill) removes material from a stationary block of steel. This is used to create flat surfaces, pockets, slots, holes, and complex 3D contours.

- Considerations for Steel: Machining steel requires rigid machines, sharp and tough carbide cutting tools with specialized coatings, and a constant flow of coolant to manage heat. Cutting speeds are generally much slower than for aluminum.

-

CNC Turning:

- Process: The steel workpiece (bar stock) rotates while a stationary cutting tool removes material. This is used to create cylindrical parts like shafts, pins, and bushings.

- Considerations for Steel: Similar to milling, turning steel requires robust tooling and lower speeds. The forces involved are high, so a powerful and rigid CNC lathe is essential.

-

Drilling and Tapping:

- Process: Drilling creates a round hole, and tapping creates internal threads within that hole.

- Considerations for Steel: Drilling steel requires strong drill bits (often cobalt or carbide) and a "pecking" cycle to break up the chips and allow coolant to reach the tip. Tapping steel requires significant torque and high-quality taps to prevent breakage.

-

Grinding:

- Process: After the main features are machined, some parts require grinding. This uses a rotating abrasive wheel to remove very small amounts of material.

- Considerations for Steel: Grinding is used on hardened steel to achieve very tight tolerances and an extremely smooth surface finish that cannot be achieved by milling or turning alone.

Process Selection Guide

| Process | Best For | Steel Challenges | Solutions |

|---|---|---|---|

| Milling | Complex 3D contours | Tool deflection, vibration | Reduced stepovers, stubby tools |

| Turning | Rotational symmetry parts | Chip control, surface finish | High-pressure coolant, chip breakers |

| Drilling | Deep holes, tight tolerances | Work hardening, walking | Pilot holes, peck drilling |

| Grinding | Ultra-fine finishes/tolerances | Heat generation, wheel loading | Continuous coolant flow |

Process Optimization

- Milling: Use variable-helix end mills to disrupt harmonic vibrations in steel cutting. I achieve 30% longer tool life with this.

- Turning: Apply wiper inserts for surface finishes under 32 Ra without polishing.

- Drilling: Spot drill exactly 90° before drilling – steel exaggerates angle errors.

- Grinding: Diamond dress wheels regularly to prevent glazing when grinding hardened steels.

I remember one project where the customer insisted on using 316 stainless steel for a thin-walled part, and we had to reduce the cutting speed to 20% of normal and change the tool every time we machined a part. It was an increase in cost, but it was the only way to meet their corrosion resistance requirements.

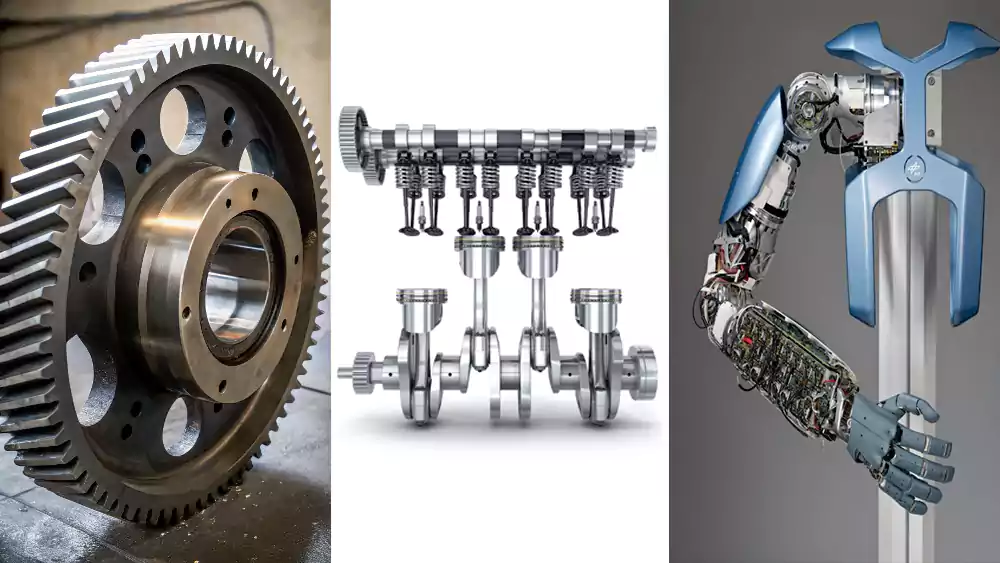

What Are the Industrial Applications of Machined Steel Parts?

Where are these custom machined steel components used? What are some real-world examples of applications that rely on the strength and durability of machined steel?

Machined steel parts are essential in industrial machinery, automotive systems, robotics, and the energy sector. They are used for gears, shafts, fixtures, molds, and other high-strength components.

Diving Deeper into Real-World Applications

The strength, hardness, and wear resistance of steel make it the material of choice for countless critical applications across many industries. For an engineer like David, who works in industrial automation, steel parts are the backbone of his machines.

Here are some key industrial applications:

-

Industrial Machinery and Automation:

- This is a massive field for machined steel. Components include high-strength gears, shafts, axles, and couplings that transmit power. It also includes precision fixtures, jigs, and machine tool components that require high rigidity and wear resistance.

-

Automotive:

- The powertrain and chassis of vehicles rely heavily on machined steel. Crankshafts, camshafts, transmission gears, and differential components are all made from high-strength alloy steel to handle extreme loads and fatigue.

-

Aerospace:

- While aerospace uses a lot of aluminum and titanium for light weight, high-strength steel alloys are still essential for critical components like landing gear, engine mounts, and high-strength fasteners where maximum strength is the top priority.

-

Mold and Die Manufacturing:

- The molds used for plastic injection molding and the dies used for stamping and forging are machined from very hard tool steels (like A2 and D2). They must be able to withstand immense pressure and high temperatures for millions of cycles.

-

Energy Sector:

- In industries like oil and gas and power generation, machined steel parts are used for valves, flanges, and components for turbines and drilling equipment that must operate reliably in harsh, high-pressure environments.

In all these applications, the precision of CNC machining is what allows these strong steel materials to be turned into functional, reliable components.

FAQs About Machining Steel

What are some of the common questions engineers have when designing steel parts? Here are some quick answers to a few frequently asked questions.

Q1: How do you prevent rust on machined steel parts?

A: This is a critical consideration. Carbon and most alloy steels will begin to rust very quickly after machining once they are exposed to air and humidity.

- Short-Term: During and immediately after machining, we use rust-inhibiting coolants and apply a light oil or rust-preventative coating.

- Long-Term: For the final part, a permanent protective finish is required. Common options include black oxide coating, zinc plating, chrome plating, or painting. The choice of finish depends on the desired level of corrosion protection and the appearance.

Q2: What is the difference between hot-rolled and cold-rolled steel?

A: A: This refers to how the raw steel stock was formed at the mill.

- Hot-Rolled Steel (HRS): The steel is rolled to its final shape at a very high temperature. It has a rough, scaly surface and looser tolerances. It is generally cheaper.

- Cold-Rolled Steel (CRS): The steel is first hot-rolled and then further processed through rollers at room temperature. This results in a smoother, more uniform surface finish and tighter dimensional tolerances. CRS is generally stronger and more suitable for precision machining.

Q3: Can I use the same tool for all steels?

A: Not recommended. Tool wear varies by material. Choose tooling based on hardness and abrasiveness.

Q4: Can all steels achieve ±0.001" tolerances?

A: No. Free-machining steels (12L14, 303SS) hold tightest tolerances. High-alloy steels move more during machining.

Q5: Does pre-hardened steel save money?

A: Sometimes. It eliminates heat-treating but increases machining costs by 20-40%. Evaluate total process cost.

Conclusion

Steel is a foundational material for CNC machining, offering unmatched strength and versatility. Selecting the right grade and process is crucial for creating durable, high-performance, cost-effective parts.

-

Learn about 12L14 steel’s unique properties and why it’s favored for high-speed machining applications. ↩

-

Exploring this topic can help you optimize production costs and improve efficiency in manufacturing. ↩

-

Discover the versatility of low-carbon steel and its common applications in construction and manufacturing. ↩

-

Explore the benefits of pre-hardened steels to understand how they can enhance your machining efficiency and reduce tool wear. ↩

-

Learn about free-machining variants to discover how they can simplify your prototyping process and improve overall productivity. ↩

-

Explore this link to understand why 4140 Alloy Steel is favored for high-strength applications and its unique properties. ↩ ↩