Expert Surface Finishing for CNC Machined Parts

Go beyond the raw machined part. Our comprehensive surface finishing services enhance aesthetic appeal, improve durability, and add critical functionality to your components.

Enhance, Protect, and Perfect Your Components

A high-quality finish is the final, critical step in manufacturing. It’s the first thing your customers see and it provides essential protection for long-term performance.

Superior Aesthetics

Achieve the perfect look and feel, from a mirror-like polish to a uniform matte texture or vibrant, custom colors.

Enhanced Durability

Increase resistance to corrosion, wear, abrasion, and chemical exposure, significantly extending the life of your parts.

Added Functionality

Introduce new properties such as electrical conductivity/insulation, lubricity, hardness, and biocompatibility.

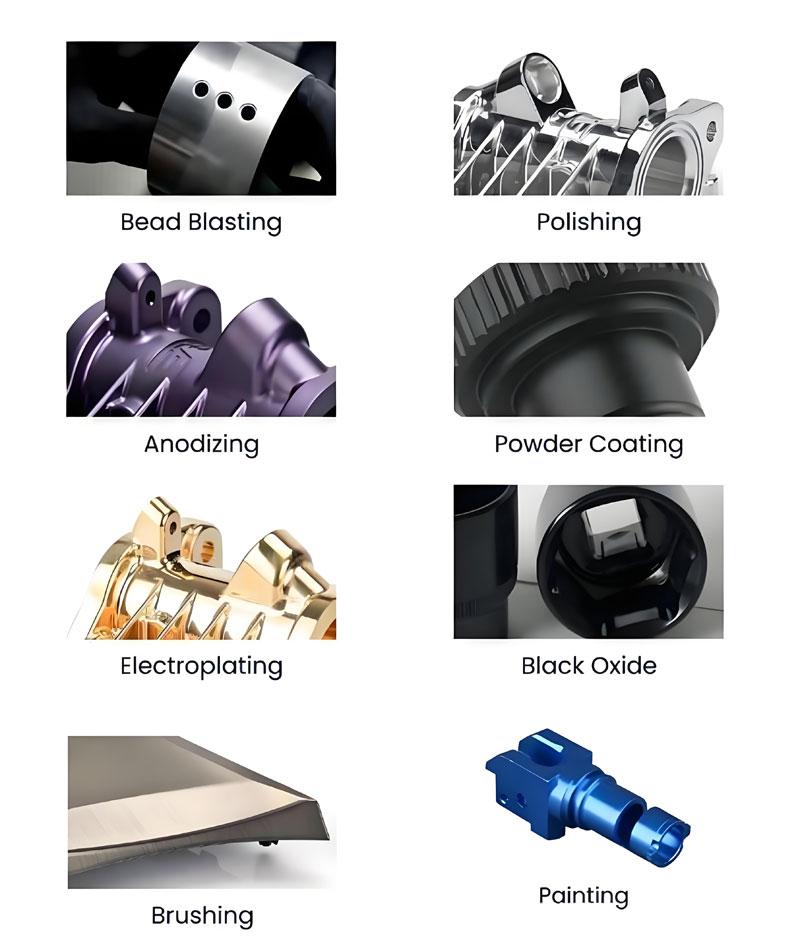

We provide a range of finishing services, including:

- Bead Blasting

- Anodizing (including hard anodizing, black/blue anodizing)

- Electroplating(Silver, Gold, Nickel, or Chrome Plating).

- Brushing

- Polishing

- Powder Coating

- Black Oxide

- Painting

- Diamond-like Carbon Coating.

- Titanium Nitride (TiN) Coating.

- Chemical Conversion Coating

- Teflon Coating

- Hardening

- Passivation

If you have any questions or need a quote, contact us to discuss your project.

CNC machining from prototype to production — with full surface finishing options.

Get fast quotes and expert support from Allied Metal.

More information about surface finishing:

Project | Material | Description | Remarks |

Manual Processing | Remove burrs and sharp edges from CNC machined products | Metal and plastic | RA3.2-1.6μm |

Sanding | Parts are polished by hand or machine | Metal and plastic | RA1.6-0.8μm |

Polishing | Polishing to achieve professional-grade shine on parts | Manual Processing | Ra-0.8-0.4μm |

Manual polishing | It helps to present the best clarity and light transmittance | PMMA or PC. | PC is second to PMMA in transparency, but it's powerful |

Spraying | We provide different screen printing spraying color mixing, UV highlighting, etc. | Metal and plastic | We use the Pantone. matching system and the Ral Classic. system. |

Surface textures | We can make different textures such as mold technology, VDI, SPI, etc. | Plastics | / |

Sandblasted/Brushed | The surface is sandblasted with different types of sand | All metals | Glass beads in different sizes: from #80 to #220 |

Anodization | It helps resist corrosion, increases surface hardness and improves wear resistance | Aluminum alloy | Clear, black, red, blue, anodized is available |

Metallization | It protects parts and improves corrosion and oxidation resistance. | Al, steel, copper, etc. | Tin, nickel, zinc (galvanized), and chromium are available. |

Vacuum Plating | It has strong adhesive properties and the coating does not come off easily and is usually used for Lighting reflectors | ABS, PC, ABS + PC, PC + GF, PET, PA, Al and zinc parts | / |

Screen Printing/Laser Engraving | Precision and permanent marks | Metal and plastic | / |

Electroplated Coating | It adds a thin layer of protective polymer to the surface. | Metal and plastic | Typical thickness variation: 50μm-150μm |

Hot treatment | It improves the hardness, wear resistance and strength of parts. | Steel | The hardness should be controlled by selecting the appropriate tempering temperature in relation to the material. |

Our Finishing Process: Quality at Every Step

We follow a rigorous process to ensure your parts are finished to the highest standards of quality and consistency.

Consultation & Selection

We work with you to choose the perfect finish based on your functional and aesthetic requirements.

Surface Preparation

Parts are meticulously cleaned, degreased, and masked to ensure optimal adhesion and a flawless result.

Professional Application

Your chosen finish is applied using state-of-the-art equipment and techniques by our experienced technicians.

Quality Inspection

Every part is inspected for color consistency, thickness, adhesion, and overall appearance before shipping.

Ready to Add the Perfect Finish?

Our team is ready to help you select and apply the ideal finish for your project. Contact us today to discuss your requirements and get a free quote.