Sheet Metal Fabrication Services

Stamping, laser cutting, bending and welding services

Sheet Metal Fabrication

Sheet metal fabrication is the process of making parts by welding thin sheets of metal together. The process is divided into three main steps:

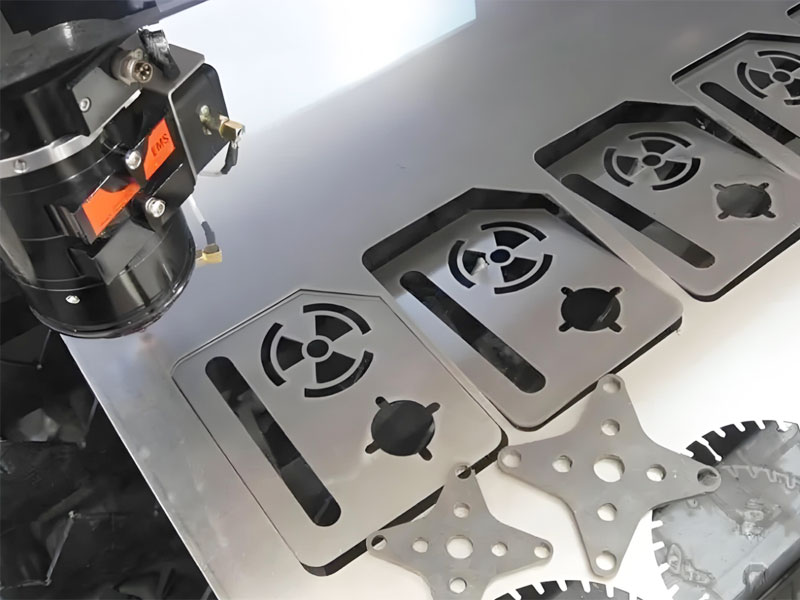

- Fabrication: This stage involves cutting the metal into the desired shape and size, and is usually performed using CNC machines or manual welders.

- Assembly: In the assembly stage, the cut parts are welded together to form complete assemblies. This process may involve different techniques such as soldering, brazing, etc.

- Finishing: The final step of finishing, which includes polishing, coating and sealing the metal, serves to protect it from the environment and improve the appearance and durability of the finished product.

Sheet metal processes:

Sheet metal forming involves a variety of processes that apply forces to a piece of metal to plastically deform the material into a desired shape, changing its geometry rather than removing any material.

Sheet metal can be bent or stretched into a variety of complex shapes, allowing the creation of complex structures with high strength and minimal amount of material.

Following are common sheet metal processes:

Suitable for simple graphic processing and mass production

The most common types of bending include C-shaped, V-shaped, and grooved.

Drawing is a metalworking process that uses tensile forces to stretch (elongate) metal, glass, or plastic.

Punching is a cutting process that produces holes and notches of various shapes and sizes.

Machining Capacity:

- Material Thickness:Cut up to 20mm Steel/20mm Plastic/15mm Stainless steel/10mm Aluminum etc.

- Length: Max 3000mm

- Width: Max 1500mm

- Tolerances: ±0.05mm

- Material Thickness: Bend up to 4mm Steel/Stainless steel/Aluminum/Brass etc.

- Length: Max 3000mm

- Width: Max 1500mm

- Tolerances: ±2°

At Allied Metal, we are not only able to provide you with all types of sheet metal forming services, but also different kinds of materials. In addition to this, there are other services such as CNC machining, CNC milling and CNC turning available for you to choose from.