Precision Manufacturing Services

Allied Metal provides comprehensive CNC machining, sheet metal fabrication, and finishing services for prototyping and production runs. With 200+ advanced machines across two facilities, we deliver precision parts with fast turnaround times.

Our Manufacturing Services

From rapid prototyping to high-volume production, we offer end-to-end manufacturing solutions for a wide range of industries.

CNC Machining

Precision CNC milling, turning, and multi-axis machining services for complex parts with tight tolerances.

Sheet Metal Fabrication

Custom sheet metal parts and enclosures with laser cutting, bending, welding, and assembly services.

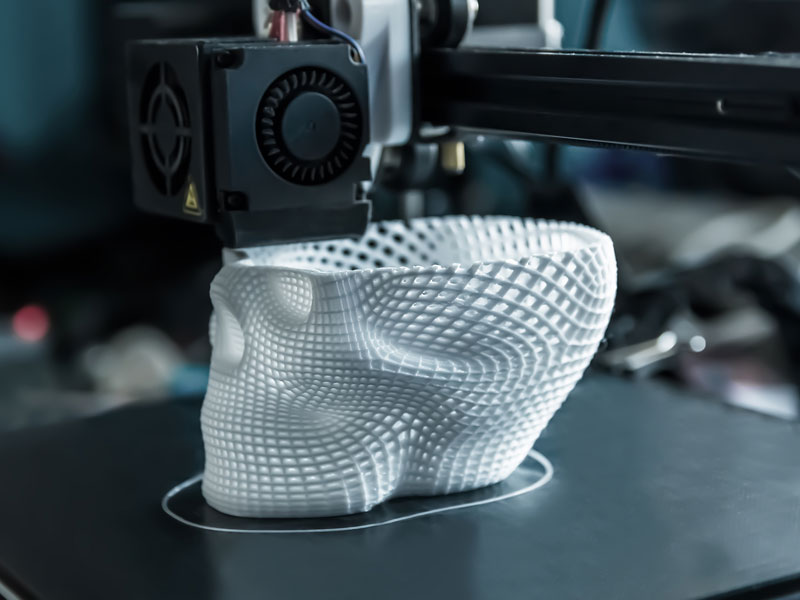

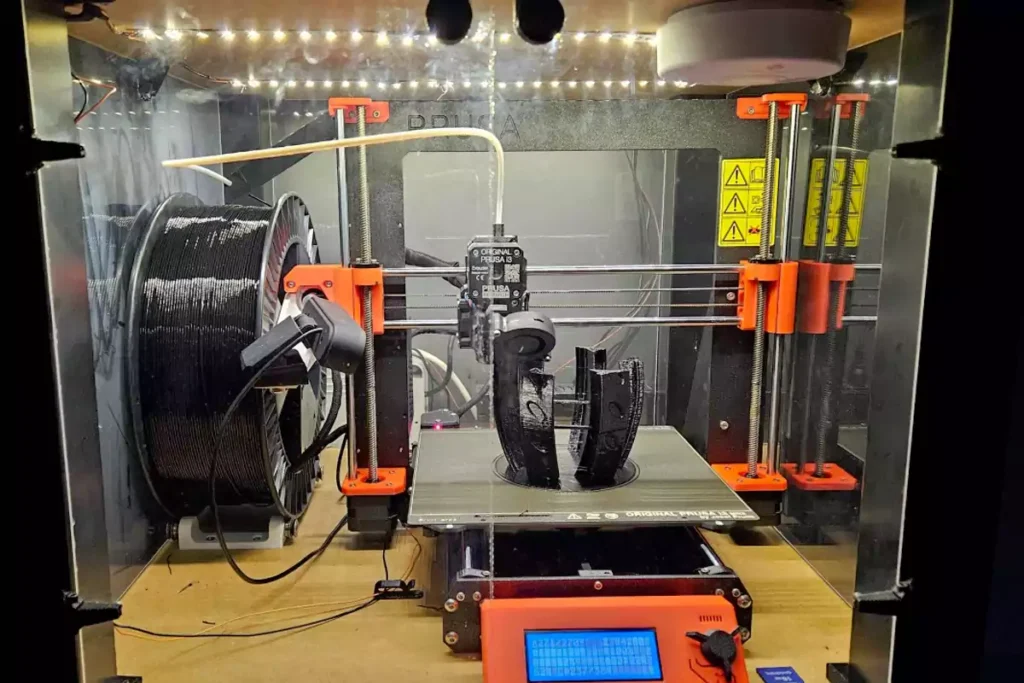

3D Printing

Rapid prototyping and production parts with SLA, SLS, and FDM technologies for various applications.

A Closer Look at Our Services

Precision CNC Machining

As a leading CNC machining manufacturer, we utilize our 200+ advanced machines to produce parts with exceptional accuracy and consistency. This is the core of our business.

CNC Milling (3, 4 & 5-Axis): Capable of producing highly complex parts for automotive, aerospace, and medical industries.

CNC Turning & Turn-Mill: Ideal for cylindrical components, shafts, and pins with high-speed precision.

Prototyping & Production: Seamlessly transition from single prototypes to high-volume production runs.

Expertise: Our team provides free DFM (Design for Manufacturability) analysis to optimize your parts for cost and speed.

Rapid Prototyping & 3D Printing

Validate your designs faster than ever. Our 3D printing services are perfect for SMEs and brand owners who need to iterate quickly and test physical models before committing to expensive tooling.

Multiple Technologies: We offer FDM, SLA, and SLS to match your specific needs for speed, surface finish, and material properties.

Form, Fit & Function: Create detailed models for ergonomic studies, assembly testing, and functional validation.

Bridge to Production: Use 3D printing to perfect your design before moving to our CNC machining services for production parts.

Professional Surface Finishing

The final finish is critical for both appearance and performance. We provide a wide range of in-house finishing options to give your parts the exact properties you need.

Anodizing (Type II & III): For durable, corrosion-resistant, and cosmetic finishes on aluminum parts. Multiple color options available.

Bead Blasting: Creates a beautiful, uniform matte or satin texture, perfect for hiding tool marks and fingerprints.

Powder Coating: A highly durable finish, tougher than conventional paint, available in a vast array of colors.

And More: Including polishing, brushing, and plating services.

Manufacturing Equipment

State-of-the-art machinery and technology for precision manufacturing

CNC Milling Machines

3-axis to 5-axis vertical and horizontal machining centers

CNC Turning Centers

Multi-axis lathes with live tooling and sub-spindle capabilities

5-Axis Machines

Simultaneous 5-axis machining for complex geometries

Swiss CNC Machines

Precision turning for small, complex components

EDM Machines

Wire and sinker EDM for cutting and forming

3D Printers

Industrial-grade additive manufacturing systems

Materials We Work With

Extensive material capabilities for diverse industry applications

Aluminum Alloys

6061, 7075, 2024, 5083

Lightweight, corrosion-resistant

Steel Alloys

4140, 4340, 8620, A36

High strength, versatile

Stainless Steel

304, 316, 17-4 PH, 15-5 PH

Corrosion-resistant, food-safe

Titanium

Ti-6Al-4V, Grade 2

Aerospace, medical applications

Brass & Bronze

C360, C544, C954

Electrical, marine applications

Carbon Steel

1018, 1045, 1215

Strong, machinable, cost-effective

Tool Steel

D2, A2, O1

High hardness, wear-resistant

Engineering Plastics

ABS, PEEK, PTFE, Nylon

Chemical resistance, electrical

Superalloys

Inconel, Hastelloy, Monel

High-temperature applications

Exotic Materials

Tungsten, Molybdenum

Specialized applications

If you don’t see the material you need listed here, please click here to view our full material selection.

Quality Control System:

We have invested over $500,000 in QC equipment and we take every order and every production part seriously.

Placing product quality at the forefront of our manufacturing process, we integrate quality control in every step to ensure superior Parts.

We identify critical quality criteria in each project and use them as benchmarks to measure the performance of the final products.

Quality Management:

- ISO 9001:2015

- In-coming Material Inspection

- Manufacturing Process Inspection

- Finished Products Inspection

- Full-dimensional inspection report

Allied Metal is your trusted CNC machining partner!

Manufacturing International Standards

Packaging Professional and Fully Protected

Customer Satisfaction

Team Work Closely

Continuous Productivity

In-company Training

Partner with a Manufacturer Who Understands Your Needs

Your success is our success. As your one-stop solution from prototype to production, we help you reduce costs, shorten lead times, and deliver a superior final product. Let our expertise become your advantage.