Titanium CNC machining

Professional Titanium CNC machining Manufacturer

- Source Factory

- Certified Materials

- No MOQ requirement

Professional Titanium CNC Machining Services

1. Lightweight Strength. Precision Built.

Titanium offers an exceptional strength-to-weight ratio — 40% lighter than steel but nearly as strong — making it the top choice for aerospace, medical, automotive, and energy applications. Its corrosion resistance and durability ensure long-term performance in the most demanding environments. CNC machining allows titanium to be shaped with precision into high-performance parts for any critical use.

2. Why Choose Allied Metal for Titanium Machining?

With 20+ years of CNC experience, Allied Metal delivers tight-tolerance titanium parts with speed and consistency. Our ISO 9001-certified facility is equipped for rapid prototyping, small-batch, and large-scale production. From complex geometries to mission-critical components, we turn your designs into reality — with expert support, fast quotes, and reliable results every time.

About the material Steel

Following are the characteristics of Titanium materials:

- High strength

- Corrosion resistance

- Non-magnetic

- High temperature resistance

- Ductility

- Excellent mechanical properties

- Biocompatibility

- Antibacterial properties

- Memory function

Titanium is one such metal, light as aluminum, hard as steel, healthy and environmentally friendly, resistant to acids and alkalis, and never rusts!

Available Materials

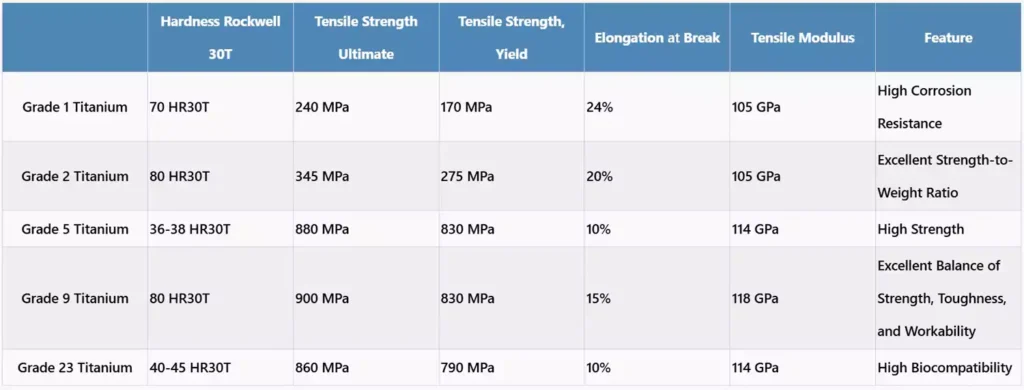

Titanium parts are corrosion-resistant, very durable, have a high melting point and are versatile. The following grades of titanium are commonly used for CNC machining:

Titanium Grade 1 | 3.7025

Titanium Grade 1 (CNC) is a commercially pure metal with excellent corrosion and impact resistance and good machinability and weldability.

Titanium Grade 2 | 3.7035

Stronger than Grade 1 and equally corrosion-resistant, excellent bio-compatibility. Grade 2 offers excellent balance of moderate strength and reasonable ductility. This material is also non-magnetic.

Titanium Grade 5 | 3.7164 | Ti6Al4V

Ti-5 is the most widely used, it is thermoformable and weldable, corrosion resistant and most acceptable to the human body (medical industry). Excellent resistance to fatigue and crack extension.

Titanium Grade 9 | 3.7194 | Ti3Al2.5V

Higher strength than Class 1 and Class 2, good corrosion resistance, toughness and workability.

Titanium Grade 23 | 3.7165 | Ti6Al4V(ELI)

Ti-Grade 23 ELI is a variant of Ti-Grade 5 and is used in medical technology due to its good biocompatibility and excellent fracture toughness and crack extension behavior.

Note: The above listed parameters for each titanium grade are for reference only. For more accurate and detailed information, please contact us.

Comparison of common titanium alloys

Our Machining Services

Frequently Asked Questions

We offer a complete titanium CNC machining service, producing custom titanium parts in grades 1, 2 and 5. Titanium parts are corrosion resistant, extremely durable, have a high melting point, and are versatile. Our network of manufacturing partners includes virtually all types of CNC milling machines and turning centers, capable of machining any part you need, from simple “post-machining” workholding to complex organic geometries with tight tolerances.

We offer a variety of surface finish options including machining, polishing, sandblasting, plating, coloring, laser etching, heat treating, screen printing, anodizing and more. Click for more surface treatment processes

CNC machining produces metal and plastic parts with excellent mechanical properties, accuracy and repeatability. We offer 3-axis and 5-axis CNC machining services.

The cost of CNC machining titanium depends on the complexity and size of the part and the type of titanium used. These variables will affect the type of machine needed, the time it takes to produce the part, and the cost of raw materials.

Based on the millions of CNC machining orders we have previously processed, we can calculate the cost of any machinable part directly from your drawings. Simply contact us for a free quote!

Titanium is very strong and has a high strength-to-weight ratio. In fact, titanium is only 5% less strong than steel but 40% lighter, making it ideal for high-tech industries such as aerospace, automotive and energy.

Can’t find the details you need? Browse additional FAQs, or get in touch with us right away for tailored support and a fast quotation.