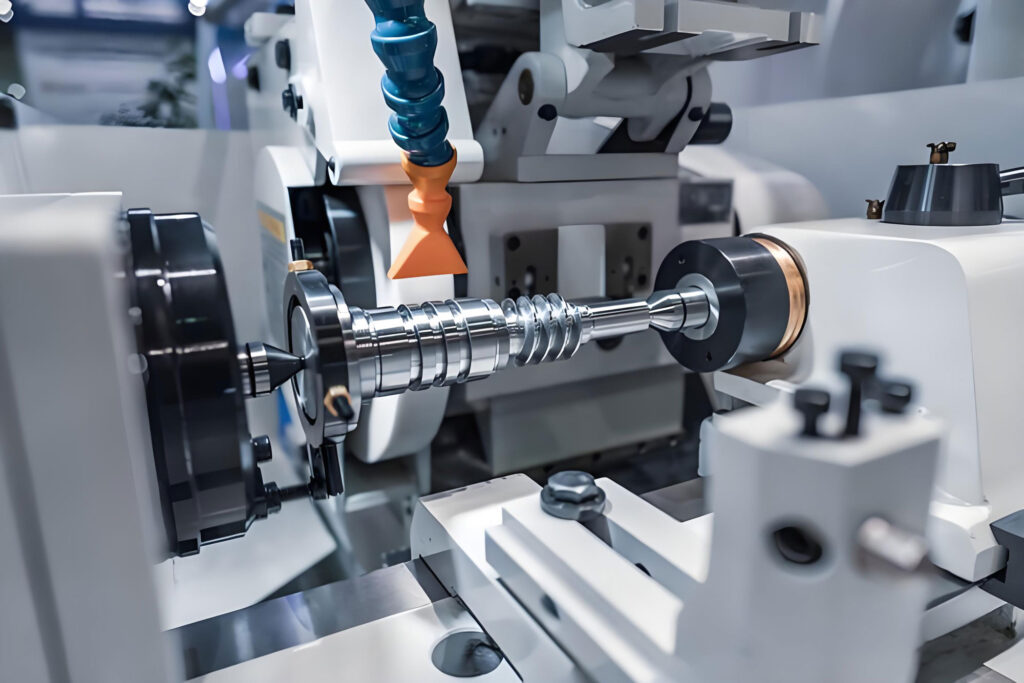

Steel CNC machining

- Source Factory

- Certified Materials

- No MOQ requirement

Professional Steel CNC Machining Services

Allied Metal offers expert CNC machining for steel parts, with 20+ years of experience and ISO 9001-certified quality.

We offer fast prototyping, low- to high-volume production, and complete support through every stage of your product development. Whether you need CNC milling, turning, or lathe work, we provide accurate, reliable results — on time and to spec.

Your Partner for Complex Steel Components

Machining steel requires power, precision, and expertise. We deliver all three, ensuring your parts perform flawlessly under pressure.

High-Strength Materials

We have extensive experience machining tough alloy and tool steels, including pre-hardened materials, for high-stress, high-wear applications.

Tight Tolerance Machining

Our fleet of 200+ advanced CNC machines, including 5-axis mills, achieves exceptional accuracy for complex geometries and critical features.

Integrated Heat Treatment

We manage the entire production chain, including post-machining heat treatment like annealing, quenching, and tempering to achieve desired hardness.

About the material Steel

Following are the characteristics of steel materials:

- Variety: there are more types of steel with different carbon content

- High strength: high tensile, compressive, flexural and shear strengths

- Good plasticity and toughness

- Good wear and corrosion resistance

- Weldability and machinability

- Environmentally friendly

- Low cost

Explore Our Range of Machinable Steels

We machine a comprehensive portfolio of steel grades. Select a category to learn more about common options.

Tool Steel:

Tool steel D2 | 1.2379 | X153CrMoV12-1 - Annealed state

Tool steel D2 (CNC) is a wear-resistant alloy that retains its hardness to a temperature of 425 °C. Used for cutting tools and dies.

Tool steel A2 | 1.2363 | X100CrMoV5-1- Annealed state

Tool steel A2 (CNC) is an air-hardened general purpose tool steel with good toughness and excellent dimensional stability. Used for molding dies.

Tool steel O1 | 1.2510 | 100MnCrW4 - Annealed state

Tool steel O1 (CNC) is an oil-hardened alloy with a high hardness of 65 HRC. Used for industrial knives and cutting tools.

Tool steel A3 - Annealed state

Tool steel A3 is an air-hardened general purpose tool steel with good toughness and excellent dimensional stability. Used for molding dies.

Tool steel S7 | 1.2355 | 50CrMoV13-15 - Annealed state

Tool steel s7 has very high impact properties. Suitable for tool and die application.

Tool steel H13 | 1.2344 | X40CrMoV5-1 - Annealed state

Tool steel H13 has an excellent combination of high toughness and fatigure resistance. It is the most common tool steel used in tooling applications.

Carbon Steel:

Mild steel 1018 | 1.1147 | C18 |16Mn

Mild steel 1018 (CNC) is a general-use alloy with good machinability, weldability, toughness, strength. Susceptible to corrosion.

Carbon steel C45 | 1.0503 | 1045 | EN8

C45 has low thermal conductivity and low ductility among wrought carbon steels.

Mild steel S355J2 | 1.0577 | 1522H | Fe 510 D

S355J2 has a high tensile strength. Compared to other carbon steels, it has high electrical conductivity but low thermal conductivity and low ductility.

Mild steel 1045 | 1.0503 | C45 | EN8

Mild steel 1045 (CNC) is a medium carbon steel with good weldability and machinability, high strength and good impact resistance. Susceptible to corrosion.

Mild Steel S235JR | 1.0038 | Fe 360 B

S235JR is a hot rolled non-alloy structural steel. It has good plasticity, toughness and weldability, certain strength and good cold bending properties.

Mild steel A36 | 1.025 | Fe 410

Mild steel A36 (CNC) is a common structural steel with good weldability. Suitable for a variety of industrial applications. Susceptible to corrosion.

Mild steel S275JR | 1.0044 | Fe430B | IS2062

As a low carbon steel specifications S275 provides low strength with good machinability and is suitable for welding.

Alloy Steel:

Alloy steel 1.7131 | 16MnCr5

Steel 1.7131 has a high surface hardness and wear resistance with good machinability.

Alloy steel 4140 | 1.7225 | EN19 | 42CrMo4

Alloy steel 4140 (CNC) has good overall properties, with good strength and toughness. Suitable for many industrial applications. Not weldable.

Alloy steel 4340 | 1.6511 | 36CrNiMo4 | EN24

Alloy steel 4340 (CNC) can be heat treated to high strength, while maintaining good toughness, wear resistance and fatigue strength. Weldable.

Alloy steel 1215 | EN1A | 1.0715

Alloy steel 1215 is a low tensile, low harden-ability carbon steel. Can be machined at higher speeds.

Note: The above listed parameters for each steel grade are for reference only. For more accurate and detailed information, please contact us.

Precision Machining for High-Load Steel Components

Delivering tight-tolerance, heat-treated alloy steel parts for demanding applications like robotics and automation — with strength and accuracy you can count on.

Hardened Alloy Steel Drive Gear

An industrial robotics client required a high-torque drive gear with exceptional wear resistance and fatigue strength. The part needed to be machined to precise gear-tooth profiles before being hardened to specification.

Our solution was to CNC mill and hob the gear from 4140 alloy steel, followed by a controlled quench and temper process to achieve a surface hardness of 55 HRC while maintaining a tough core.

- Material: Alloy Steel 4140

- Services: 5-Axis CNC Milling, Gear Hobbing, Heat Treatment

- Hardness: 55 HRC (Rockwell C)

- Application: Industrial Robotics, Automation

Our Machining Services

Frequently Asked Questions

Low Maintenance. Steel CNC parts last longer than other metals due to their high dimensional stability.

Rugged and durable parts. With excellent mechanical properties, great durability and good machinability, it’s feasible to manufacture high-quality parts using steel CNC machining.

Wide range of material options. With a wide range of steel types, such as mild steel, alloy steel, stainless steel and tool steel, you can choose the most suitable steel for your CNC parts.

Steel parts are used in a wide range of applications, some of the more common are: medical devices, construction equipment, automotive parts, machine parts, and vacuum and pressure vessels.

The exact price depends on the part structure, order quantity, machining process and finish requirements. If you have a part you need to consult, you can email us directly for a free quote! Email account: quote@alliedcn.com

We offer a variety of surface finish options including machining, polishing, sandblasting, plating, coloring, laser etching, heat treating, screen printing, anodizing and more. Click for more surface treatment processes

CNC machining produces metal and plastic parts with excellent mechanical properties, accuracy and repeatability. We offer 3-axis and 5-axis CNC machining services.

Didn’t find the question you were looking for? No worries—click to view more FAQs, or contact us directly for further information and a quote.