Copper CNC machining

Professional Copper CNC machining Manufacturer

- Source Factory

- Certified Materials

- No MOQ requirement

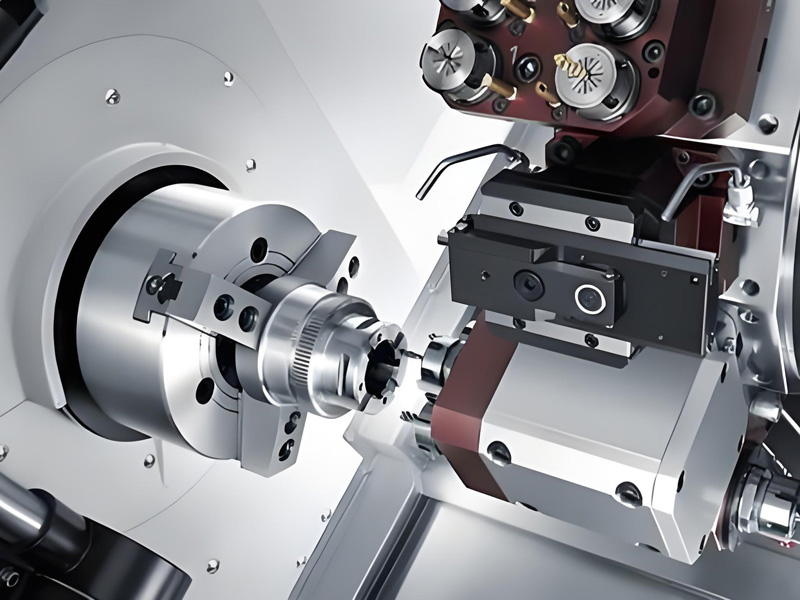

Professional Copper CNC Machining Services

Allied Metal has over 20 years of experience in CNC machining services with state-of-the-art CNC machining equipment and a team of experts.

Our ISO9001 certified, highly qualified machine shop is capable of performing any custom design, whether it’s a simple or complex project.

We offer rapid prototyping, low-volume machining, and high-volume production of end-use parts.

Our fast and precise CNC machining capabilities include CNC milling, CNC turning, and CNC lathe services for both flexible production and all phases of your product development.

Why Machine with Copper?

Copper’s unique properties make it the definitive choice for applications where performance and reliability are non-negotiable.

Unrivaled Conductivity

The highest electrical and thermal conductivity of any non-precious metal, ensuring maximum efficiency and minimal energy loss in your electrical systems and heat sinks.

Excellent Corrosion Resistance

Naturally resists corrosion and oxidization, guaranteeing long-term reliability for components in harsh environments, from marine applications to industrial machinery.

Superior Ductility & Formability

Its inherent ductility allows for the creation of complex shapes and intricate features without fracturing, perfect for custom connectors and detailed parts.

Sustainability

Copper is 100% recyclable without any loss of performance, making it an environmentally responsible choice for modern product development.

About the material Copper

Following are the characteristics of Copper materials:

- Natural non-magnetic metal

- Excellent thermal and electrical conductivity

- Good ductility and easy processing

- Excellent mechanical performance and precision

- Strong corrosion resistance

- Recyclable and reusable

Available Materials

The most common copper used for CNC milling or CNC turning is C110 and C101.

Copper C110 | CU ETP

Copper (C110) is a pure at 99.90% copper alloy, with universal for electrical applications high thermal conductivity and good corrosion resistance.

Copper C101 | CU OFE

Copper (C101), 99.99% pure, is a copper alloy with excellent conductivity and high corrosion resistance and toughness.

Precision Machining Product Showcase

Custom machining of complex copper parts for various industries!

Custom Copper Busbar for EV Battery Systems

A leading electric vehicle technology firm needed a high-current busbar for their new battery pack. The component required maximum electrical conductivity, tight dimensional tolerances to ensure a perfect fit, and absolute reliability under extreme thermal loads.

We leveraged our 5-axis CNC capabilities to machine the complex geometry from C110 ETP copper, ensuring optimal performance and safety for this critical application.

- Material: Copper C110 (ETP)

- Key Tolerance: ±0.02 mm on connection surfaces

- Services: 5-Axis CNC Milling, Quality Inspection

- Application: Electric Vehicles, Power Distribution

Assurance of quality and precision

For mission-critical copper components, there is no room for error. Our ISO 9001 certified quality management system is integrated into every step of the process, from material sourcing to final delivery.

Certified Material Sourcing

We source only high-purity copper from trusted mills and provide full material traceability certificates with your order.

Advanced CMM Inspection

Our imported coordinate measuring machines (CMMs) verify every critical dimension against your CAD model to ensure perfect accuracy.

From Prototype to Production

Our rigorous quality standards are applied equally whether we are making a single prototype or 10,000+ production parts.

Machining Services Offered

CNC Lathe, CNC Turning, 3 Axis CNC Milling, 5 Axis CNC Machining Service for simple and complex geometrical parts.

A variety of surface treatments can be added to the parts, such as anodizing, sandblasting, powder coating, plating, and polishing.

Sheet metal forming consists of processes such as bending, spinning, drawing or stretching by means of a die or stamping tool.