Brass CNC machining

Professional Brass CNC Machining Manufacturer

- Low friction

- Good conductivity

- Golden color appearance

Professional Brass CNC Machining Services

Brass CNC Machining Services for Custom Precision Parts

Looking for high-quality brass CNC parts with tight tolerances and smooth finishes? Brass is one of the most machinable metals — ideal for precision components used in plumbing, electrical systems, medical devices, and decorative fittings. Its strength, corrosion resistance, and excellent electrical conductivity make it a top choice across industries.

Trusted Brass CNC Parts Manufacturer — Allied Metal

With over 20 years of experience, Allied Metal is a leading brass parts manufacturer offering custom CNC machining services. Our ISO 9001-certified facility handles everything from rapid prototyping to high-volume production. We deliver fast lead times, consistent quality, and expert support for every project.

About the material Steel

Following are the characteristics of Brass materials:

- Low friction

- Good conductivity

- Excellent mechanical properties

- High workability

- Good tensile strength

- Natural corrosion resistance

- Attractive metal color

Our Brass Machining Capabilities

We harness state-of-the-art technology to offer a comprehensive suite of brass machining services.

Multi-Axis CNC Milling

Our 3, 4, and 5-axis CNC mills produce complex geometries with incredible accuracy, perfect for intricate brass components.

CNC Turning & Swiss Lathes

Ideal for cylindrical parts, fittings, and connectors. Our Swiss-type lathes excel at producing small, complex parts in high volumes.

Advanced Surface Finishes

From as-machined to polished, brushed, plated (nickel, chrome, gold), or passivated, we provide the perfect finish for your application.

Prototyping to Production

We provide a one-stop solution, supporting your project from the initial rapid prototype all the way to mass production.

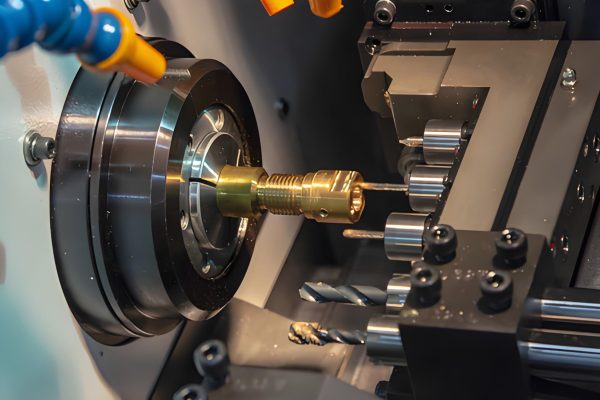

Project Showcase: Precision in Practice

Here’s a real-world example of how we turn complex requirements into tangible, high-performance components.

High-Performance RF Coaxial Connector Housing

A client in the telecommunications industry required a custom housing for a new line of high-frequency connectors. The part demanded exceptional dimensional stability for signal integrity and superior corrosion resistance for long-term field deployment.

Our solution involved 5-axis CNC milling of C360 Brass, followed by a bright nickel plating finish to enhance durability and performance.

- Material: Brass C360 (Free-Cutting Brass)

- Key Tolerance: ±0.005 mm on internal bore

- Services: 5-Axis CNC Milling, CNC Turning

- Surface Finish: Bright Nickel Plating

- Application: Telecommunications, RF Equipment

Available Materials

Brass is a metal alloy with good machinability and good electrical conductivity. It is well suited for applications requiring low friction. The following grades of brass are commonly used in machining:

Brass Cz121 | C38500 | 2.0401 | CuZn39Pb3

Brass Cz121/C360 (CNC) is a highly machinable alloy with good tensile strength and natural corrosion resistance. Ideal for parts that require low friction.

Brass C360 | 2.0375 | CuZn36Pb3 | 319 grade 2

Brass C360 (CNC) is highly machinable alloy with good tensile strength and natural corrosion resistance. Ideal for parts that require low friction.

Note: The above listed parameters for each brass grade are for reference only. For more accurate and detailed information, please contact us.

Frequently Asked Questions

We offer CNC machined brass parts in Brass C360, an extremely machinable alloy with good tensile strength and natural corrosion resistance. It is also ideal for applications that require low friction. Of course, if you have other specialized machining needs, please contact us directly for material details!

We offer a variety of surface finish options including machining, polishing, sandblasting, plating, coloring, laser etching, heat treating, screen printing, anodizing and more. Click for more surface treatment processes

CNC machining produces metal and plastic parts with excellent mechanical properties, accuracy and repeatability. We offer 3-axis and 5-axis CNC machining services.

The cost of CNC machining brass depends on the complexity and size of the part and the type of brass used. These variables will affect the type of machine needed, the time it takes to produce the part, and the cost of raw materials.

Based on the millions of CNC machining orders we have previously processed, we can calculate the cost of any machinable part directly from your drawings. Simply contact us for a free quote!

Copper is a pure metal known for its excellent electrical and thermal conductivity, making it ideal for wiring and electronics. It’s also more malleable and corrosion-resistant than many other metals.

Brass, on the other hand, is an alloy made primarily of copper and zinc. It’s harder than copper, has a golden appearance, and is easier to machine. Brass is commonly used in plumbing, decorative items, and musical instruments due to its strength and workability.

In summary, copper excels in conductivity and corrosion resistance, while brass offers greater strength and machinability.