Aluminum CNC machining

Professional Aluminum CNC Machining Manufacturer

- Source Factory

- Certified Materials

- No MOQ requirement

Need a Reliable Supplier for Machined Aluminum Parts?

We are specialists in precision CNC machining of aluminum alloys. From the versatile 6061 to the high-strength 7075, we transform raw stock into finished components with exceptional accuracy and surface finish.

Allied Metal delivers fast, high-precision aluminum CNC machining backed by 20+ years of experience and ISO 9001-certified quality.

From simple designs to complex parts, we offer rapid prototyping, low- to high-volume production, and full support for your entire project.

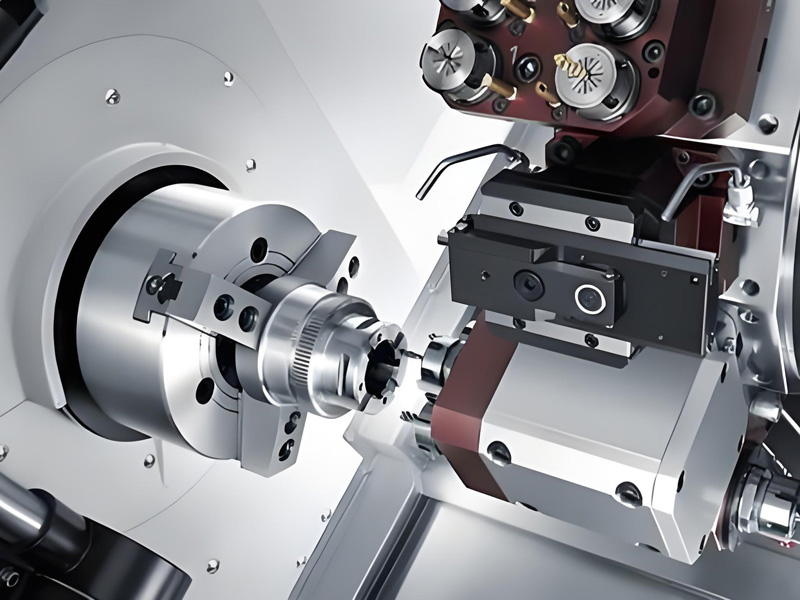

Our capabilities include CNC milling, turning, and lathe work — with tight tolerances and quick turnaround.

About the material Aluminum

Following are the characteristics of aluminum alloy materials:

- High thermal and electrical conductivity

- Superior corrosion resistance

- Excellent machinability

- Good ductility

- Good mechanical properties

- Excellent strength-to-weight ratio

- Overall versatility

- Low density and light weight

- Low cost

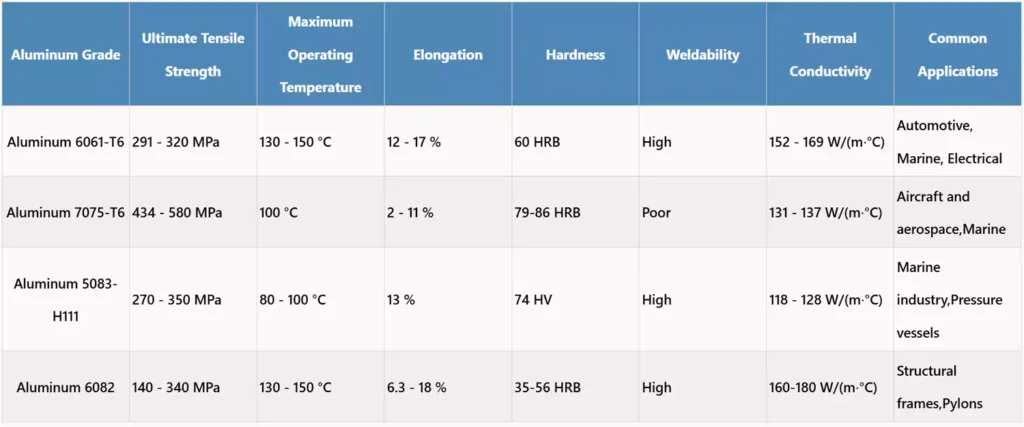

Comparison Of Common Aluminum Alloys

Note: The parameters of each grade of aluminum alloy in the above table are for reference only. For more accurate and detailed information, please contact us.

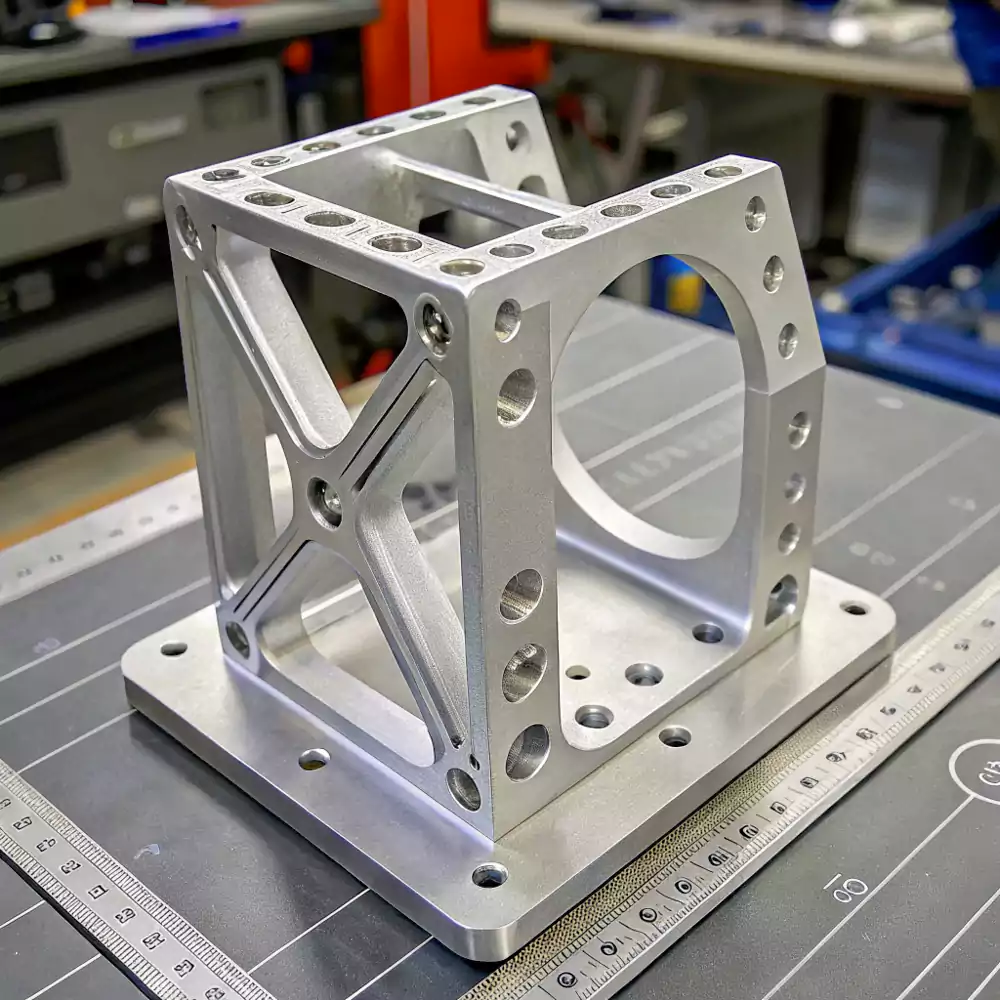

Precision Aluminum Machining for Aerospace-Grade Performance

Discover how we deliver lightweight, high-strength 7075-T6 aluminum components with ultra-thin walls and zero distortion — perfect for aerospace and high-demand applications.

From Billet to Flight-Ready: Aerospace-Grade Precision

See how we transformed a solid block of high-strength 7075-T6 aluminum into a mission-critical aerospace component, balancing extreme strength with minimal weight through advanced 5-axis machining.

- Material: Aerospace Grade 7075-T6 Aluminum

- Services: 5-Axis CNC Milling, Deburring, Type II Anodizing

- Key Feature: Achieved critical wall thickness of 0.8mm without distortion.

The Right Alloy for Every Application

We machine a wide spectrum of aluminum alloys, each with unique properties suited for different needs. Explore some of our most common material families.

6000 Series(Versatile)

6061-T6

Excellent strength-to-weight ratio, good machinability, and weldability. Perfect for structural frames, electronics enclosures, and prototypes.

6063-T5

Known for its superb surface finish and corrosion resistance. Ideal for intricate extrusions, window frames, and decorative parts.

6082-T6

Slightly higher tensile strength than 6061. Commonly used in Europe for highly stressed applications like trusses, bridges, and transport parts.

7000 Series (High-Strength)

7075-T6

One of the strongest aluminum alloys available. Comparable to many steels in strength, but at a fraction of the weight. Used in aerospace and high-performance parts.

7050-T7451

Offers a better balance of strength, stress corrosion cracking resistance, and toughness than 7075. Ideal for thick plate aerospace applications.

5000 Series (Marine Grade)

5052-H32

Highest strength of the non-heat-treatable grades. Excellent corrosion resistance in marine environments. Used for sheet metal, tanks, and marine hardware.

5083-H116

Exceptional performance in saltwater and industrial chemical environments. The top choice for shipbuilding, pressure vessels, and rail cars.

2000 Series (Copper Alloy)

2024-T3

Known for its high strength and excellent fatigue resistance. Widely used for aircraft structures, fuselage components, and wing tension members.

Our Aluminum Alloy Machining Services

Sheet metal forming consists of processes such as bending, spinning, drawing or stretching by means of a die or stamping tool.

Our Four-Step Path to Perfection

We’ve refined our manufacturing process to ensure a seamless experience and exceptional results, from your initial design to the final delivered part.

Engineering Review

Our engineers analyze your CAD model and provide DFM feedback to optimize for cost and quality.

Precision Machining

Your parts are programmed and machined on our fleet of 200+ advanced CNC mills and lathes.

Surface Finishing

We provide in-house finishing options including anodizing, bead blasting, and powder coating.

Quality Assurance

Every part is rigorously inspected using CMMs and high-precision tools to guarantee conformity.