CNC machining services

Medical parts manufacturing

- Material Certification

- Factory Prices

- No minimum order

- Strict tolerances and complex geometric shapes

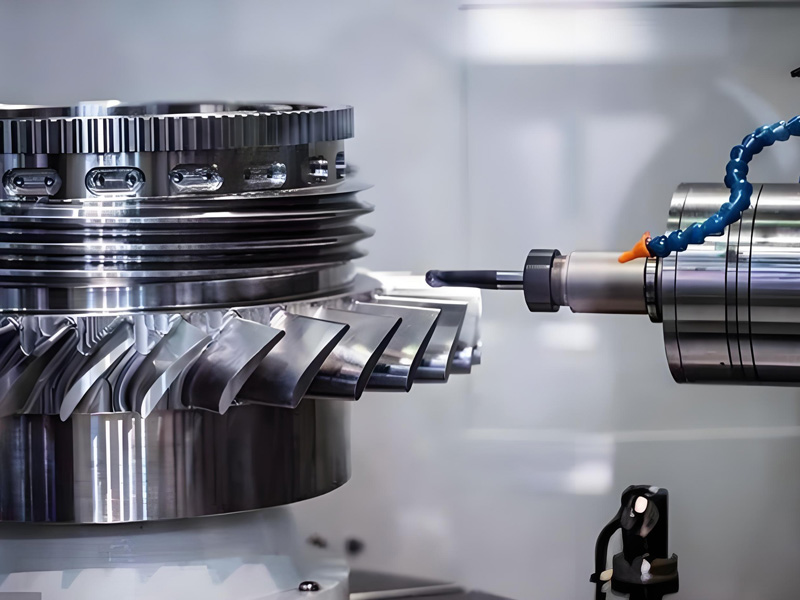

CNC Machining & Medical

Medical Prototyping and Custom Parts Manufacturing Medical machinery is complex and requires parts that are brand new with no room for error. Parts must be durable, high quality, and have smooth surfaces. CNC machining can easily pass the high standards of medical devices because it enables the product’s material reduction manufacturing process through multi-axis operation. What’s more, CNC machining can accommodate complex designs and can be manufactured on a large scale. This method of production lends itself to mass manufacturing.

Our CNC machining advantages

CNC technology is an important tool in the industrial machinery industry. It represents a technological advancement and an increase in the level of automation that enables machine tools to operate precisely and efficiently. Advantages of CNC machining of machinery and equipment parts include:

- High precision and efficiency

- Complex shaped parts can be manufactured

- Stable and reliable processing quality

- High production efficiency

- Solve the problem of varied parts, small batch size

- Reduce waste and cost.

With over 20 years of CNC machining history, Allied Metal can offer extensive expertise in medical device machining. We meet industry standards for efficiency, precision, cost-effectiveness and rapid delivery.

Processing Material Compliance

For medical devices, it is critical to ensure that materials meet regulatory standards such as biocompatibility and sterilizability.

Many medical device components are made from materials that must comply with FDA, ISO and other relevant medical standards.

Our company works with domestic compliant material suppliers and imports from Europe and the United States for specialized materials to meet customer needs. We also provide material certification reports to ensure that the parts we produce meet all material requirements.

We can customize parts for your Medical

- Medical Technology Prototypes

- Electronic Medical Device Parts

- Diagnostic Equipment Parts

- Testing Instrument Parts

- Medical Teaching Aids Parts

- Surgical tools

- Prosthetic Components

- Surgical implants

- Laboratory accessories

- Dental equipment accessories

- Decontouring models

- Others

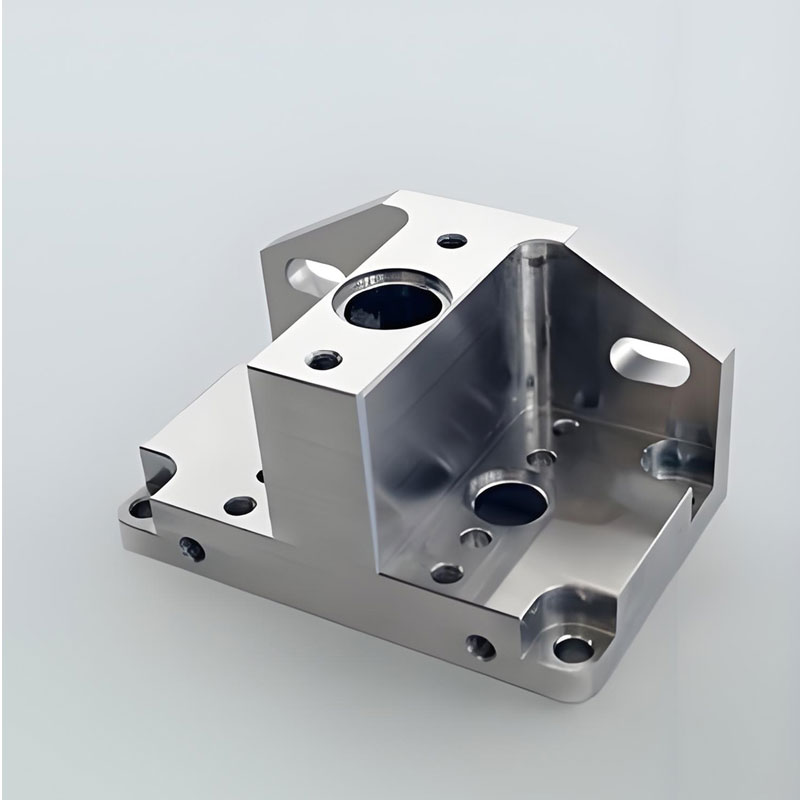

Our Precision CNC Machining Services

We are one of the leading CNC machining service providers in China.

Our 3-axis, 4-axis, and 5-axis CNC milling, turning centers, and CNC lathes are capable of producing precision, high-quality CNC parts to your custom specifications.

We offer high-quality prototyping, low-volume and high-volume precision manufacturing services to meet your product development needs at different stages.

Components we have produced

How to control CNC machining costs for medical projects?

Manufacturing medical components demands strict compliance with regulations and standards to guarantee safety and effectiveness. This often involves selecting specialized materials, incorporating complex geometric designs, and implementing additional safety measures, all of which can significantly increase CNC machining costs. So, how can you manage these factors to maximize value for money in CNC machining for medical projects?

Optimize cost efficiency by accurately calculating required raw material sizes and machine run times.

Optimize the process scheduling scheme to reduce processing difficulty and improve yield.

Select materials that balance cost and compliance with the quality and performance of the medical device.

Maintain strict quality control to minimize rework and scrap, ensure high yields and reduce unit costs.

Materials we offer for medical parts

Through our network of vetted manufacturing partners, we can offer a wide range of durable materials. Medical device materials can be selected from over 30 metal alloys and hundreds of industrial grade plastics.

Metal: aluminum, aircraft aluminum, brass, bronze, carbon steel, alloy steel, stainless steel, titanium alloy, nickel alloy and so on;

Plastics: PA66, ABS, POM, PVC, PEEK, PAI, acrylic; Wood: mahogany, ebony, pearwood, rosewood, etc.