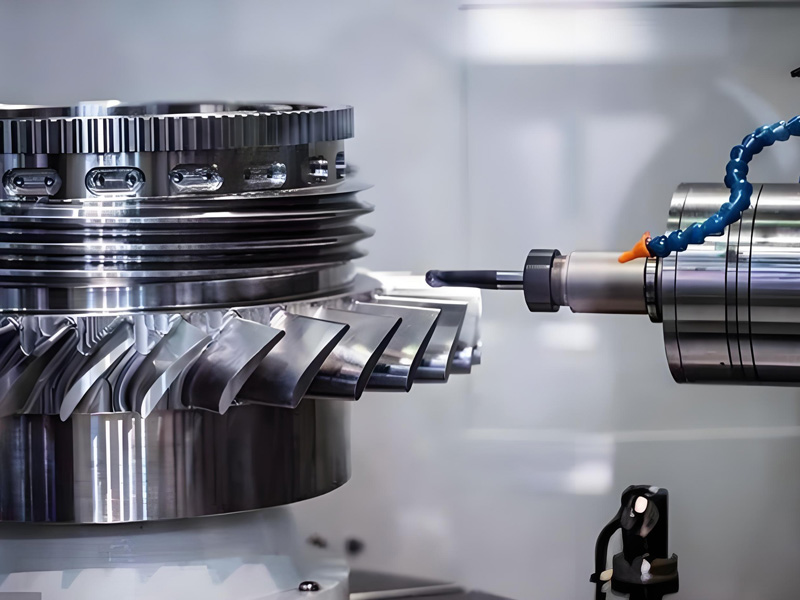

CNC machining services

Consumer Electronics manufacturing

- Material Certification

- Factory Prices

- No minimum order

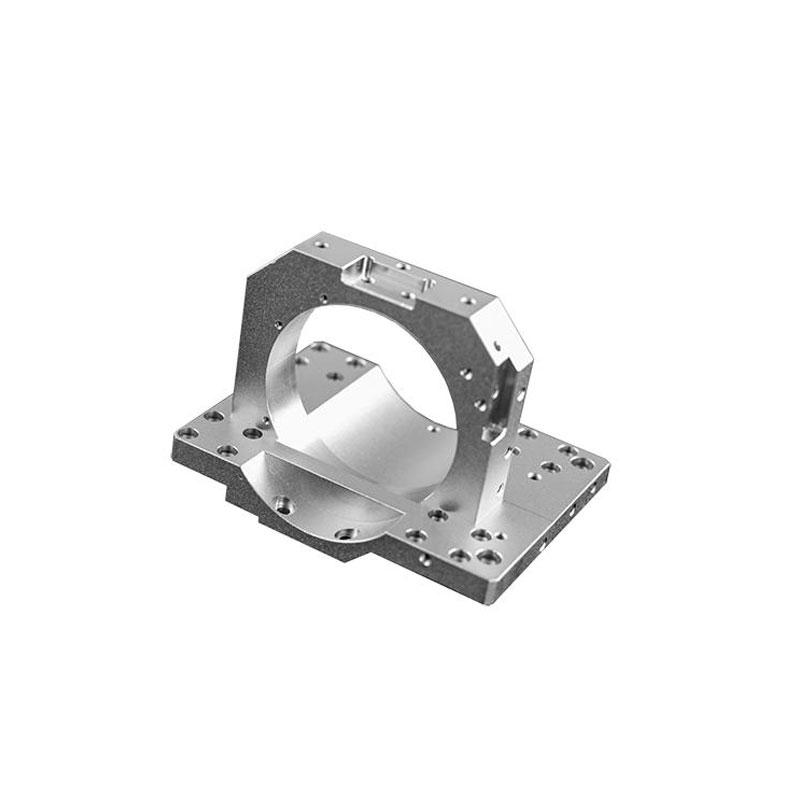

- Strict tolerances and complex geometric shapes

- Huge selection of high-quality materials & finishes

CNC Machining & Consumer Electronics

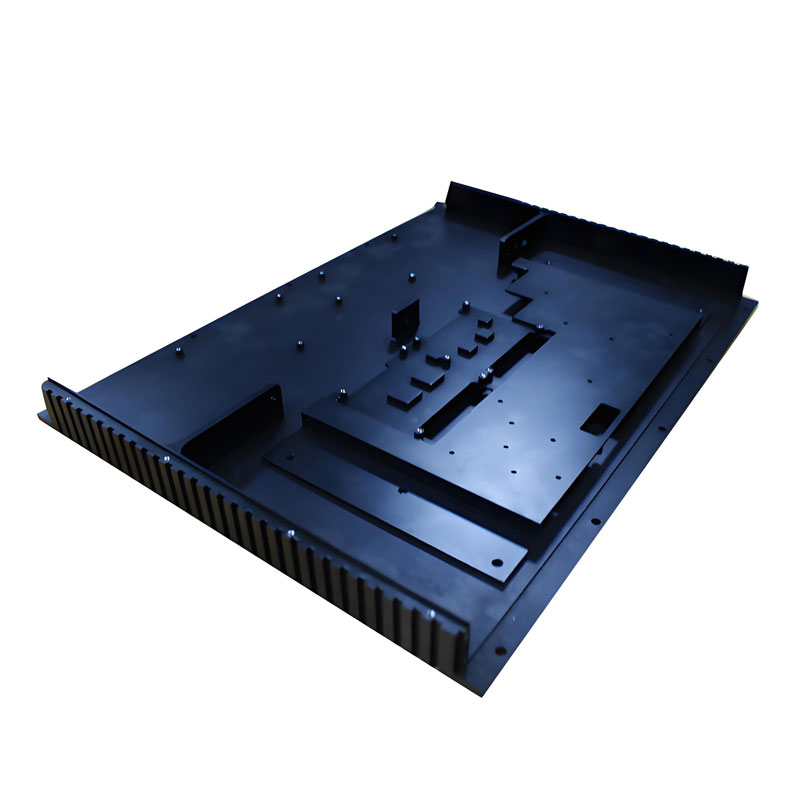

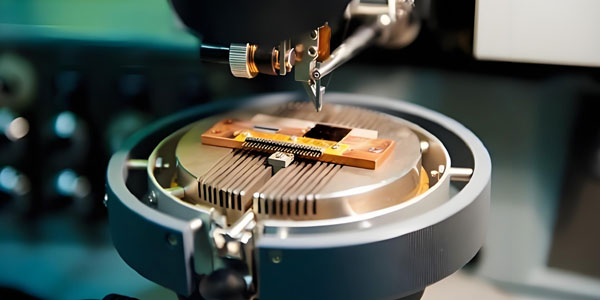

As the popularity of consumer electronics and communication devices increases the demand for small, precision parts that are high-strength and corrosion-resistant, CNC machining ensures that these parts meet specifications and is widely used in the manufacture of plastic housings and the internal structure of electronic products.

CNC machining technology is perfectly suited to the fine tolerances and high-quality surface finishes required for electronics.

Our CNC machining advantages

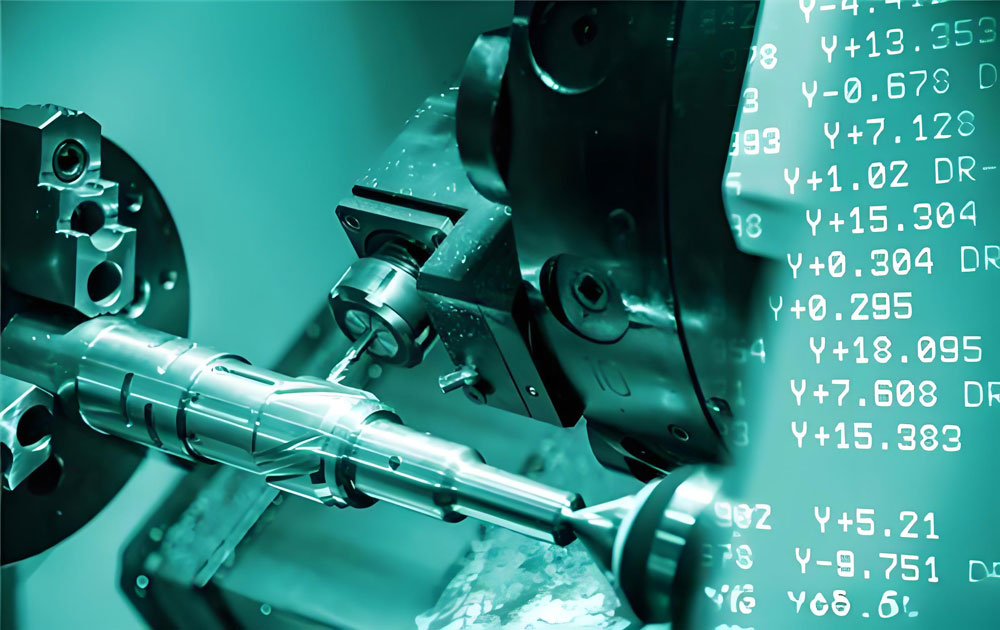

Allied Metal is deeply involved in CNC and has become an expert in the machining of electronic parts. We can handle a wide range of critical features of a part and quickly develop the right program.

- High efficiency

- High precision

- Highly automated

- Machining Stability

- Flexible machinability

- Cost saving and fast delivery

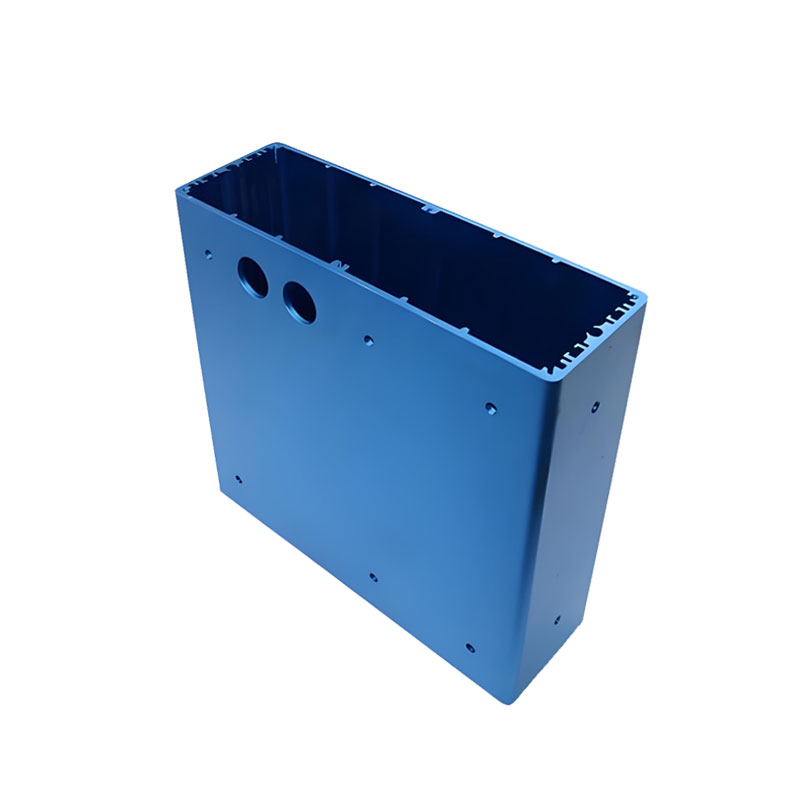

We can customize parts for your Consumer Electronics

CNC machining in the electronics industry has a wide range of applications, not limited to optoelectronic devices, communications equipment and semiconductor equipment components processing.

- Circuit Boards

- Housings

- Connectors

- Keypad components

- Components for smart door locks

- Smart control panels

- Sensor housings

- Transistors

- Capacitors

- Semiconductors

- Diodes and circuit chips

- Others

Our Precision CNC Machining Services

We are one of the leading CNC machining service providers in China.

Our 3-axis, 4-axis, and 5-axis CNC milling, turning centers, and CNC lathes are capable of producing precision, high-quality CNC parts to your custom specifications.

We offer high-quality prototyping, low-volume and high-volume precision manufacturing services to meet your product development needs at different stages.

Consumer Electronics we have produced

How to control CNC machining costs for Consumer Electronics?

Developing consumer electronics and computer components requires advanced manufacturing techniques to ensure accuracy, performance and finish. This often involves the selection of specialized materials, complex designs and additional surface finishes, all of which add to the cost of CNC machining. So how can you effectively manage these factors to maximize the cost-effectiveness of your electronics project?

Optimize cost efficiency by accurately calculating required raw material sizes and machine run times.

Optimize the process scheduling scheme to reduce processing difficulty and improve yield.

Select materials that strike a balance between cost and compliance with electronic product quality and performance.

Maintain strict quality control to minimize rework and scrap, ensure high yields and reduce unit costs.