POM(Delrin/Acetal)

Professional POM CNC Machining Manufacturer

- Material Certification

- Factory Prices

- No minimum order

Professional POM CNC Machining Services

POM, also known as polyacetal or polyacetal, is a thermoplastic material. It is often used as a substitute for metal in machined parts because of its high wear resistance, low friction, and resistance to abrasion, chemicals, and moisture. In addition, it can withstand a wide range of temperatures.

Allied Metal brings over 20 years of CNC machining expertise, equipped with advanced machinery and a skilled team.

Our ISO9001-certified shop handles any custom design, from simple to complex projects.

We offer rapid prototyping, low-volume machining, and high-volume production.

Our precise CNC services include milling, turning, and lathe work, supporting all stages of your product development.

About the material POM

Following are the characteristics of POM materials:

- High strength and rigidity

- Good wear resistance

- Good chemical resistance

- Good dimensional stability

- Excellent electrical properties

- Low water absorption

- High temperature resistance

Available Materials

POM is an engineering thermoplastic with high stiffness, high precision, low friction and easy processing. It is often used to make precision parts that require high stiffness, low friction and excellent dimensional stability.

Following are common POM plastic processing grades:

100T Tough Grade

Has high viscosity and provides excellent toughness and durability.

100AF

Has a high viscosity for applications requiring higher abrasion resistance.

100ST

A super tough grade that provides higher impact strength and durability.

500P

Injection grade with medium to high viscosity for applications requiring good flow and moldability.

900P

Injection molding grade, high viscosity, for applications requiring high abrasion resistance.

500CL

Wear grade for applications requiring high abrasion resistance and durability.

525GR

Reinforced grade, medium viscosity, reinforced with glass fiber to provide higher strength and rigidity.

527UV

Glass fiber reinforced grade, high stiffness, low warpage, for applications requiring good dimensional stability.

107UV

UV resistant grade, provides protection against UV rays for extended service life.

Note: These grades are based on the physical and chemical properties of the POM material, such as toughness, viscosity, abrasion resistance, rigidity, etc., to meet different needs. Selecting the right grade of POM material for CNC machining is critical to ensure product performance and longevity.

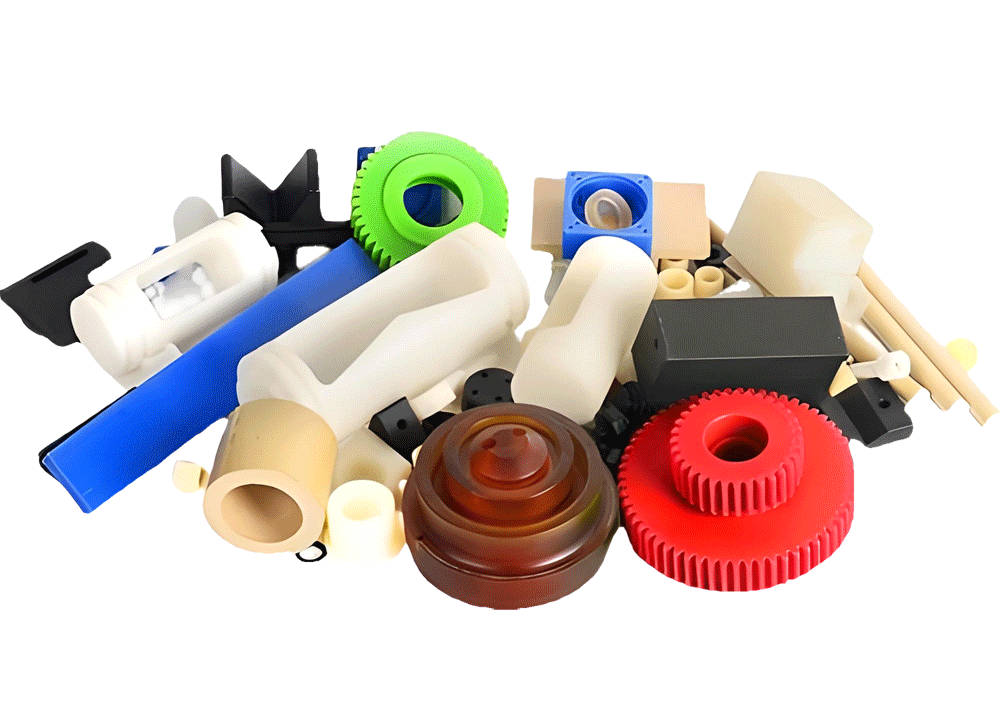

Applications for POM plastic

POM can be used to manufacture a variety of high-strength, high-rigidity parts, such as bearings, gears, sliders, pneumatic components and so on. In addition, POM can also be used to manufacture molding molds, such as injection molds, blow molds, etc.

Because POM has excellent abrasion resistance and chemical resistance, it is widely used in automobile manufacturing. For example, engine valve guides, valve stems, oil seals and other components.

POM has good electrical insulation properties and stable dielectric constant, so it can be used in the manufacture of electronic components and electrical accessories, such as connectors, sockets, switches and so on.

Due to good biocompatibility and mechanical properties, it is widely used in the medical field, POM can be used in the manufacture of medical devices and human implants, such as joint prostheses, dental implants, etc.

In addition to the above applications, POM can also be used to manufacture sports equipment, furniture, toys and other daily necessities.

Our Machining Services

Frequently Asked Questions

POM, also known as acetal or polyacetal, is a thermoplastic material known for its exceptional strength, stiffness, toughness, and low coefficient of friction. Delrin belongs to the wider category of POM plastics and is a particular brand of acetal. Despite different manufacturers, Delrin and other POM acetal materials share similar properties. POM is commonly used as a substitute for metals in mechanical parts due to its high wear resistance, low friction, and resistance to abrasion, chemicals, and moisture. Additionally, it can withstand a wide range of temperatures.

POM can be CNC machined into complex shapes and is available in various grades with different properties, such as enhanced stiffness or improved chemical resistance, to suit different applications. It is used in a wide range of industries, including automotive, electrical, medical, and consumer goods.

Because Allied Metal’s CNC machines have 3, 4, or 5-axis CNC milling and turning capabilities, they can be used to create simple and complex shapes with strict tolerances and excellent dimensional stability.

Our team of engineers and mechanics with over 20 years of experience in CNC machining specializes in CNC machining of POM and other thermoplastic materials to meet your exact specifications.

1. CNC machining allows POM parts to be produced with a high degree of precision and accuracy, enabling the creation of complex shapes and features with tight tolerances.

2. CNC machines can produce large quantities of POM parts with consistent quality and dimensional accuracy, ensuring that each part meets the required specifications.

3. CNC machining is a fast and efficient process that reduces production time and costs compared to other methods of manufacturing POM parts.

4. CNC machining can produce POM parts in a wide variety of shapes and sizes, allowing customized parts to be created to meet specific design requirements.

5. POM is a material with excellent strength, stiffness and wear resistance, enabling it to perform well in a wide range of environmental conditions and temperatures.

6.CNC machining produces minimal scrap, helping to reduce material costs and minimize environmental impact.

1. Optimize the part design. The complexity and size of the POM part affects the machining time and cost.

2. Optimize machining parameters (such as cutting speed, feed rate and depth of cut) to help reduce machining time and improve part quality.

3. Select a more suitable material grade.

4. Selecting a reputable and experienced CNC machining company will help ensure efficient and economical production of POM parts.

Allied Metal is one of the best CNC machining service providers in China. It has state-of-the-art CNC production equipment, a dedicated team of professionals, the ability to offer more than 100 certified material options, and expertise in part design and process optimization. If you have a part that needs to be machined, contact us today for a free quote.

The choice of POM or ABS depends on the specific application requirements. For example, for applications requiring high mechanical strength, wear resistance, and dimensional stability, POM may be a better choice. ABS, on the other hand, may be more appropriate for applications requiring good surface gloss, ease of processing, and a wide range of applications. Therefore, it is not possible to generalize that POM is better than ABS plastic, but rather, the right material should be selected based on specific application scenarios and needs.