End-to-End CNC Machining Services

We offer various CNC manufacturing services

Whether you need a prototype to validate a design or a mass-produced final product, Allied Metal can fulfill your needs!

CNC Turning

High-precision turning for cylindrical parts using automated lathes. Ideal for shafts, bushings, and custom fasteners with tight tolerances.

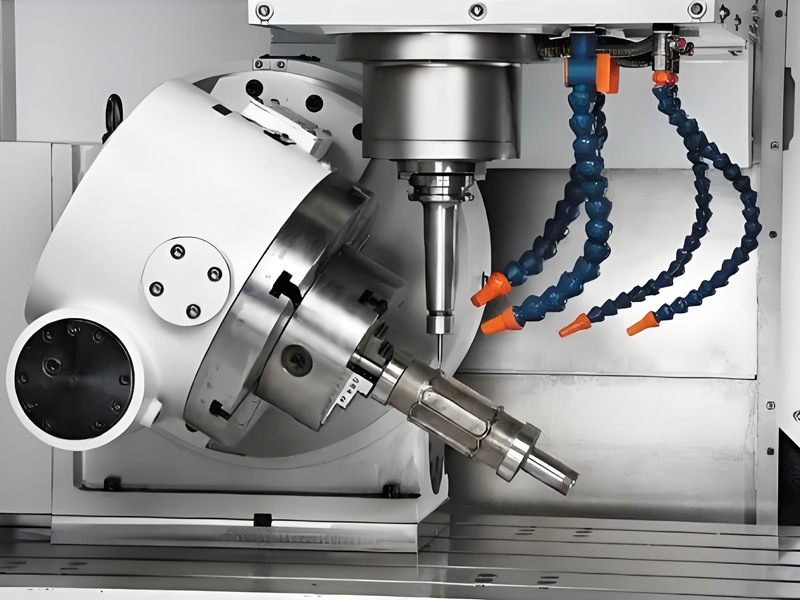

CNC Milling

Multi-axis CNC milling for complex geometries and high-accuracy components. Perfect for prototyping and production of detailed parts.

Wire EDM Machining

Ultra-precise wire cutting down to ±0.0001″. No tool pressure, perfect for delicate or hardened metal components.

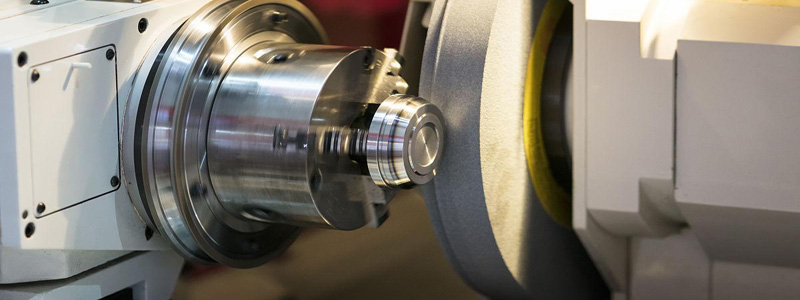

CNC Grinding

Computer-controlled grinding for ultra-smooth finishes and tight dimensional control. Removes blemishes and improves surface precision.

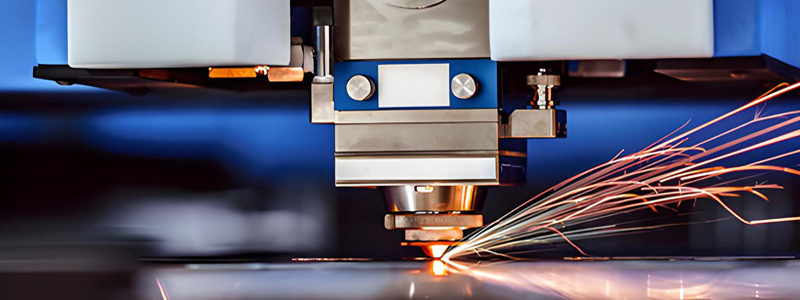

Laser Stamping

Fast, clean laser cutting for metals like aluminum and titanium. Delivers sharp edges and consistent shapes for slots, holes, and trims.

Sheet Metal Fabrication

Cost-effective fabrication for flat or bent metal parts. Ideal for enclosures, brackets, and parts with uniform thickness.

The Allied Metal Advantage: Why Partner With Us?

We are more than just a supplier; we are a strategic partner dedicated to your success. Our clients choose us for our commitment to quality, scale, and service.

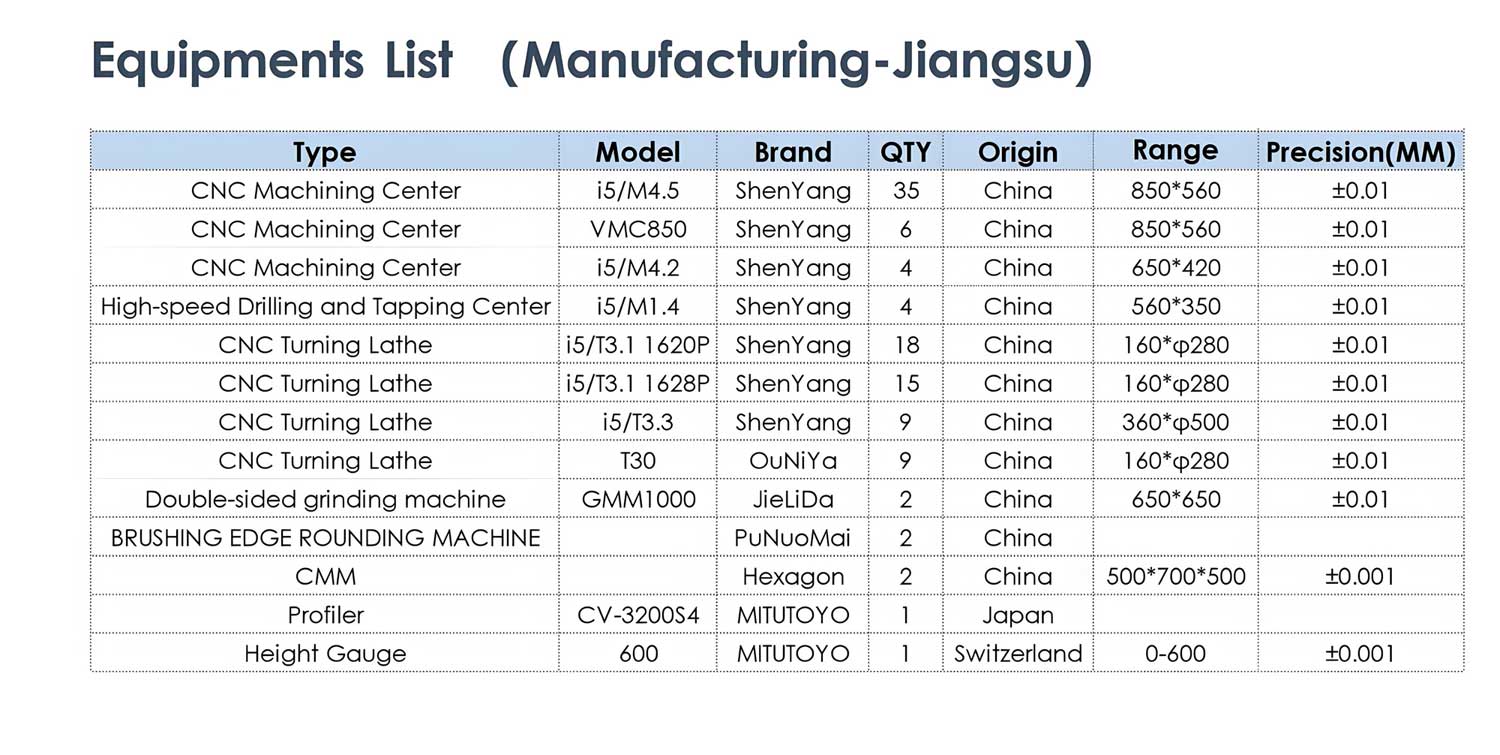

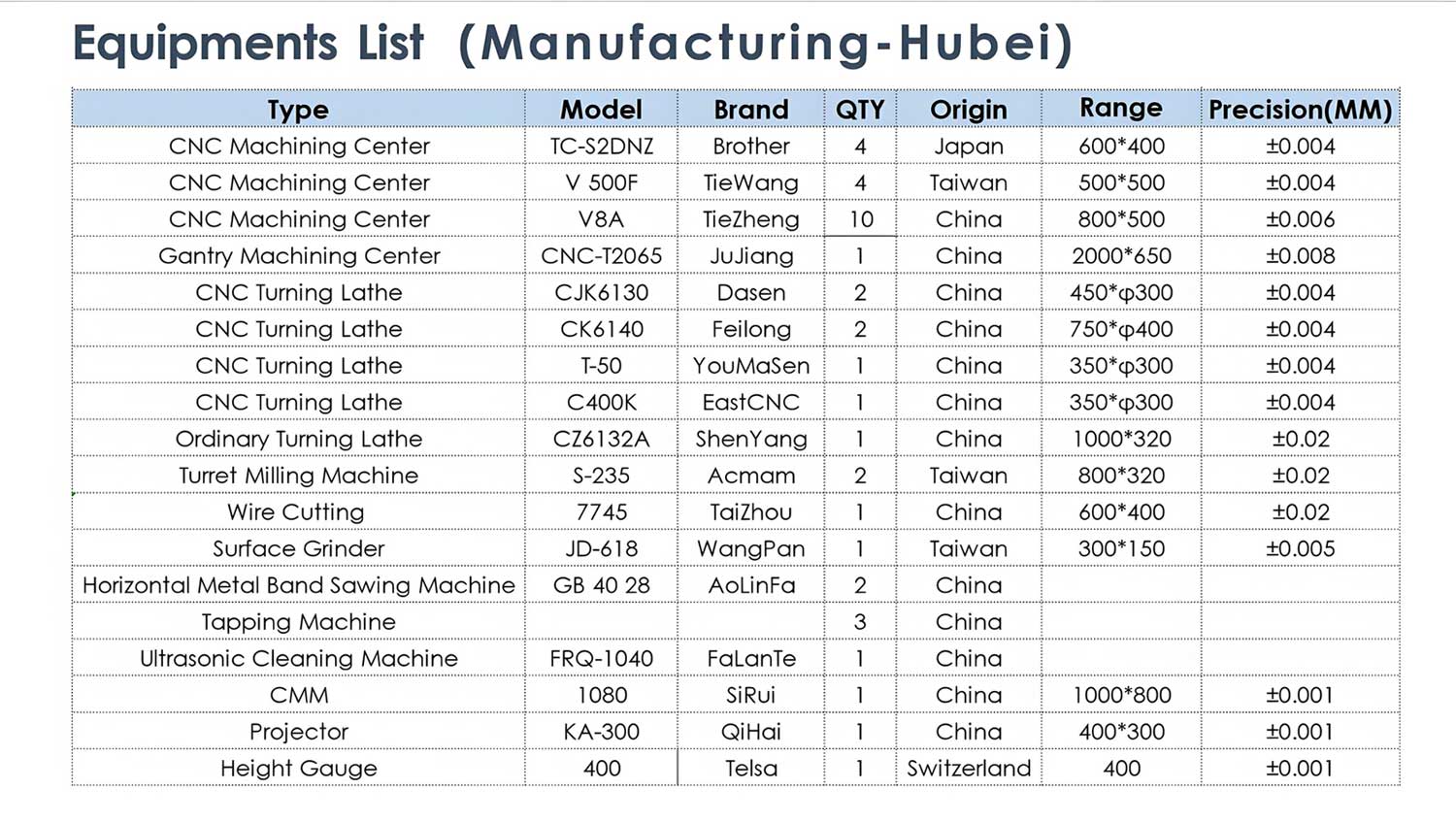

Massive Capacity, Any Scale

With 2 factories and over 200+ CNC machines, we have the capacity to handle everything from single prototypes to 10,000+ unit production runs with consistent quality and lead times.

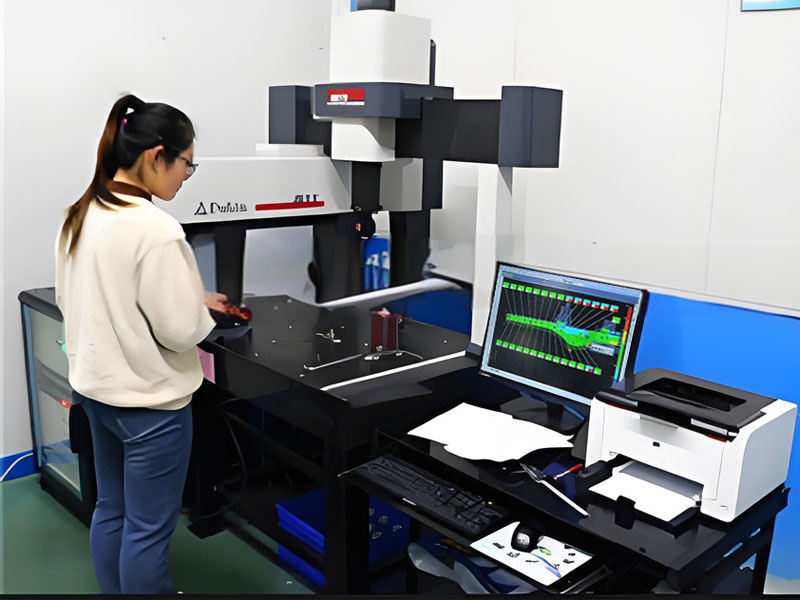

Uncompromising Quality

Our dedicated QA labs are equipped with imported CMMs, projectors, and material testers to ensure every part meets your specifications and our rigorous standards.

One-Stop Solution

Simplify your supply chain. We offer machining, 3D printing, a wide array of surface finishes, and light assembly, providing a complete solution under one roof.

Our State-of-the-Art Machining Facilities

Our investment in technology is an investment in your product’s quality. We utilize world-class equipment to achieve superior results.

- 5-Axis CNC Machining Centers: For highly complex parts with organic surfaces, machined in a single setup for maximum accuracy.

- CNC Mill-Turn Centers: Combining milling and turning capabilities to produce intricate parts with exceptional efficiency.

- High-Speed Machining (HSM): Reducing cycle times and improving surface finishes on aluminum and other soft metals.

- Advanced Metrology Lab: Featuring high-precision inspection equipment from ZEISS, Mitutoyo, and Hexagon to validate every critical dimension.

- Comprehensive Support Equipment: Including CNC grinding machines, laser cutters, and ultrasonic cleaning lines for a complete manufacturing process.

From Concept to Component in 4 Simple Steps

Our streamlined process ensures a smooth and transparent experience, delivering quality parts on time, every time.

Quote & DFM Analysis

Submit your CAD files. Our engineers review your design and provide a detailed quote along with Design for Manufacturability (DFM) feedback to optimize for cost and quality.

Programming & Setup

Once approved, your project is assigned to a dedicated project manager. Our expert programmers create the toolpaths and our technicians prepare the CNC machines.

Precision Machining

Your parts are machined from your specified material on our advanced equipment, monitored by skilled operators to ensure consistency throughout the run.

Inspection & Delivery

Every part undergoes a rigorous quality inspection. Once approved, parts are carefully packaged and shipped globally to your doorstep.