Precision CNC machining Supplier

Precision Parts, From Prototype to Production

- Highest precision: ±0.005mm/100mm

- Source processing plant, competitive price

- ISO 9001 Certified

- Fast delivery within 7 days

- Worldwide delivery

- Real factory visits are welcome!

CUSTOMERS

300+ satisfied repeat customers and counting

QUALITY

100% outgoing inspection

SERVICE

24 hours a day

HIGH TECH

Synergy of software and hardware

FAST

Prototypes in 2 days fastest

Allied Metal is your best solution specialist for CNC Machining.

From rapid prototyping to mass production, we are participating the industry revolution.

CNC PROTOTYPING

Lower energy consumption and faster time during the various stages production.

LOW VOLUME TO MASS PRODUCTION

It meets your high precision and quality needs.

CAPABILITY

State of the art Equipment, 2 manufacturing base, 100+ employees.

SERVICE

We aim to always put the customer first in every decision we make.

Our Manufacturing Capabilities

Provides high-quality prototyping, low and large-volume manufacturing services.

To make your product ideas a reality through high-tech CNC equipment and ensure your parts are shipped on time.

If you’re looking for the right machine shop in China, please contact us!

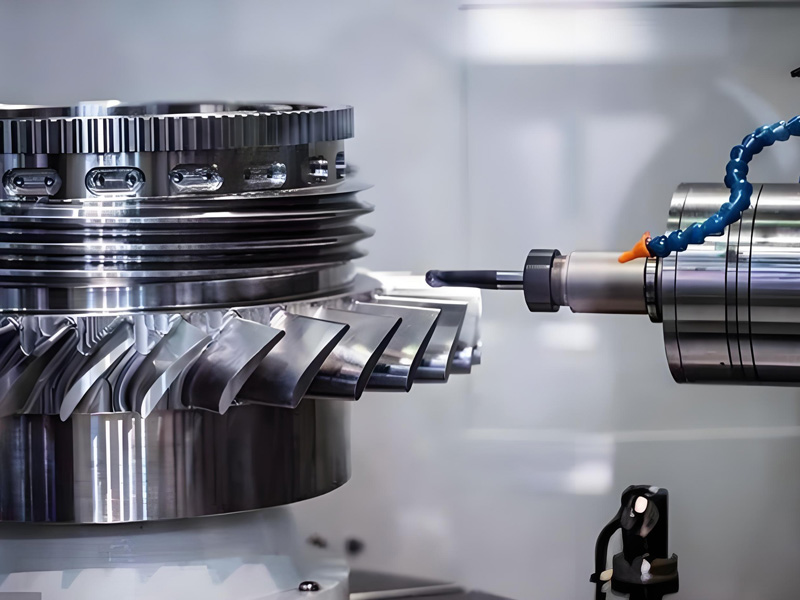

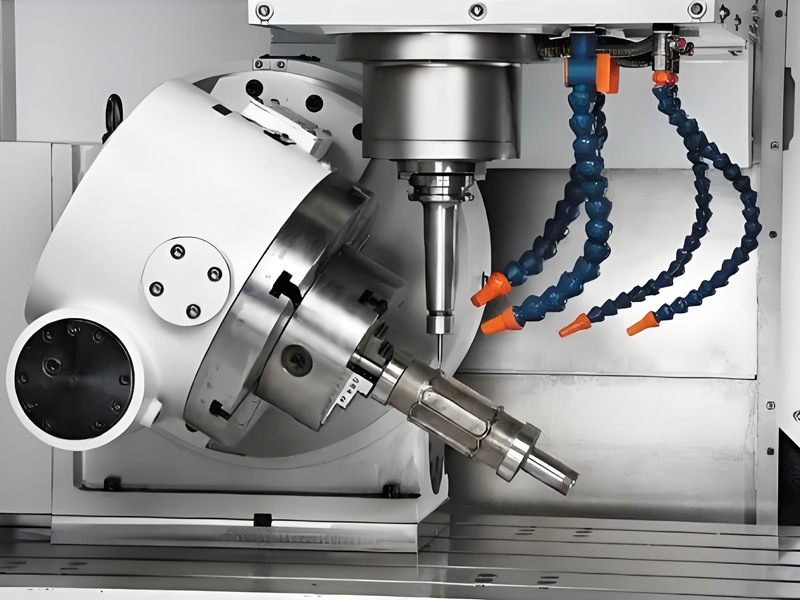

CNC Machining

CNC Lathe, CNC Turning, 3 Axis CNC Milling, 5 Axis CNC Machining Service for simple and complex geometrical parts.

Surface Finishes

A variety of surface treatments can be added to the parts, such as anodizing, sandblasting, powder coating, plating, and polishing.

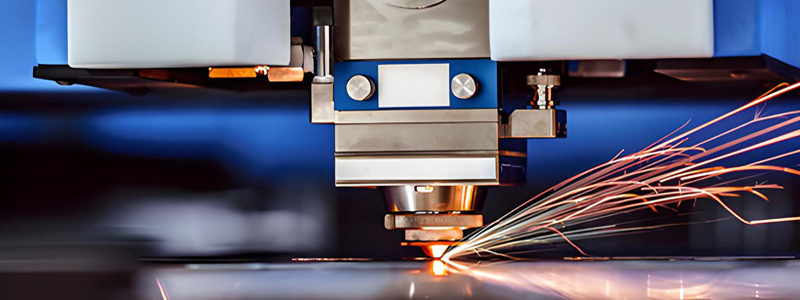

Sheet Metal Fabrication

Sheet metal forming consists of processes such as bending, spinning, drawing or stretching by means of a die or stamping tool.

We offer various CNC manufacturing services

Whether you need a prototype to validate a design or a mass-produced final product, Allied Metal can fulfill your needs!

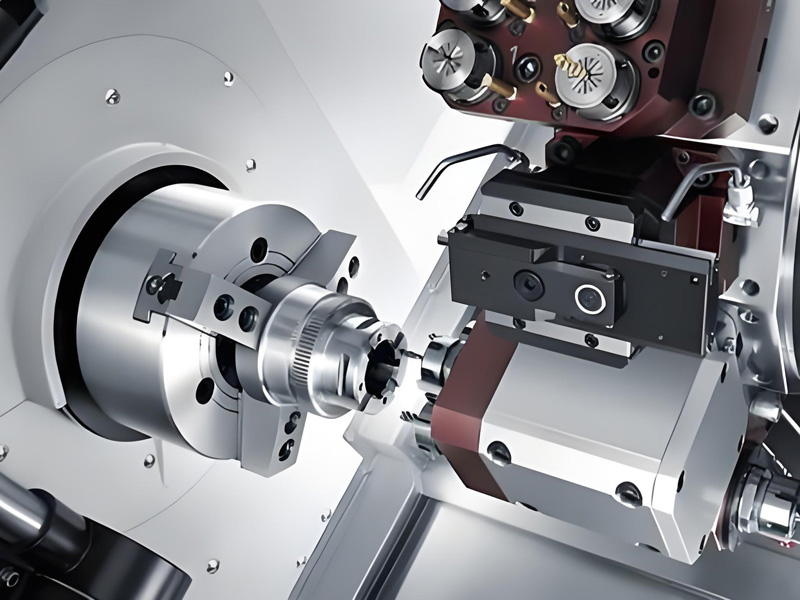

CNC Turning

Achieve high-precision cylindrical parts with our advanced CNC turning services. Ideal for producing shafts, bushings, and custom round components with tight tolerances and smooth finishes.

CNC Milling

From complex geometries to detailed surface features, our CNC milling delivers exceptional accuracy in both prototyping and full-scale production. Perfect for housings, brackets, and precision molds.

Wire EDM Machining

Cut intricate shapes and ultra-fine details with micron-level precision. Our Wire EDM process is ideal for hard metals, tight tolerances, and parts that require zero thermal distortion.

CNC Grinding

When surface finish and dimensional accuracy matter, CNC grinding provides the perfect finish. We deliver consistent results for hardened parts, dies, and components with critical tolerances.

Laser Stamping

Fast, clean, and highly repeatable—our laser stamping service creates crisp cuts and intricate profiles without tooling costs. Great for custom metal tags, enclosures, and prototype panels.

Sheet Metal Fabrication

From single prototypes to full-scale production runs, our sheet metal services include cutting, bending, welding, and finishing—all under one roof. Built to meet your specs, every time.

100+ Materials Available For Selection

We can provide instant quotes for over 100 metals and plastics! Quickly select the material that better suits the needs of your CNC machining project.

Nature Of Material:

Aluminum is a lightweight metal known for its strength, corrosion resistance, and conductivity. It is commonly used in machine parts, common household hardware, automotive components, and enclosures. Aluminum provides a high strength-to-weight ratio, good thermal and electrical conductivity, and corrosion resistance.

Brass is an alloy composed of copper and zinc, known for its attractive appearance and easy machinability. It is used in applications such as decorative items, jewelry, hardware, and musical instruments. Brass also offers good corrosion resistance and antimicrobial properties.

ABS is a thermoplastic polymer known for its toughness and impact resistance. It is commonly used in applications such as prototyping, automotive parts, enclosures, and consumer goods. ABS offers good strength and durability, is easy to machine, is available in various colors, and is cost-effective.

ACM panel is a lightweight composite material consisting of a thin aluminum sheet bonded to a polyethylene or fire-retardant core. It finds applications in signage, architectural cladding, exhibition displays, and interior design. ACM Panel provides excellent flatness, a high strength-to-weight ratio, weather resistance, and ease of shaping and cutting, making it suitable for outdoor use.

Baltic birch plywood is a type of plywood made from multiple layers of birch veneer. It is known for its strength and durability. It is commonly used in furniture, cabinetry, jigs, and decorative items. Baltic birch plywood offers stability, void-free construction, high strength, good screw-holding ability, and suitability for intricate cuts and engraving.

HDPE is a versatile thermoplastic known for its high strength-to-weight ratio and resistance to chemicals. It finds applications in kitchen cutting boards, marine applications, wear strips, and storage containers. HDPE is lightweight, exhibits excellent chemical resistance, has low moisture absorption, is easy to machine, and is cost-effective.

MDF is a type of engineered wood product that is manufactured by breaking down residuals of hardwood or softwood into wood fibers. These fibers are then combined with resin and compressed to form a dense and uniform board. MDF finds widespread use in applications such as cabinetry, furniture, signage, and decorative panels. One of its key advantages is the smooth and consistent surface it offers. MDF is also highly machinable, making it easy to shape and carve. Additionally, it is known for its affordability, stability, and suitability for painting and veneering processes.

Polycarbonate is a transparent thermoplastic known for its high impact resistance and clarity. It is used in applications such as protective screens, machine guards, lenses, and electronic components. Polycarbonate exhibits excellent impact resistance, high optical clarity, ease of shaping and forming, and good electrical insulation properties.

CNC routing is commonly employed in cutting and shaping foam materials such as expanded polystyrene (EPS) and polyurethane foam. Foam is frequently used in packaging, insulation, theatrical props, and architectural modeling.

UHMW is a tough and abrasion-resistant thermoplastic with a high molecular weight. It finds applications in bearings, wear strips, conveyor components, and chute liners. UHMW offers excellent abrasion resistance, self-lubrication, low friction, and high impact strength.

CNC routing is used to process composite materials, including fiberglass-reinforced plastic (FRP), carbon-fiber-reinforced plastic (CFRP), and other composite laminates. CFRP exhibits high strength and stiffness, is light for its strength, has excellent fatigue resistance, and low thermal expansion. This material is widely used in the aerospace, automotive, marine, and sports industrie.

Common Material Models:

• Aluminium 2007

• Aluminium 2017

• Aluminium2024

• Aluminium5052

• Aluminium 6060

• Aluminium 6061

• Aluminium6063

• Aluminium6068

• Aluminium 6082

• Aluminium 7075

• C3604

• C3602

• Brass Ms58

• Brass C36000

• H62(C28000, CuZn40)

• H65(C27000, CuZn35)

• H68(C26800, CuZn35)

• Hpb59(C37700, CuZn38Pb2)

• HPb62(C36000,CuZn36Pb3)

• Copper E-Cu57 / E-Cu58

• Copper C260

• Copper C360

• Copper C1100

• Copper T27300

• Copper T27600

• Copper T28200

• Stainless Steel 303

• Stainless Steel 304

• Stainless Steel 304L

• Stainless Steel 316L

• Stainless Steel 316Ti

• Stainless Steel 416

• Stainless Steel420

• Stainless Steel430

• Marine-grade stainless steel

• Titan Grade 2 / 3.7035

• Titan Grade 5 / 3.7164 / 3.7165 / Ti-6Al-4V

• ABS

• Acrylic

• Industrial PEEK

• Nylon 6 / PA 6

• PC (Polycarbonate)

• PEEK glass-filled

• Polypropylene (PP)

• POM / Delrin acetal

• PTFE / Teflon

• PVDF / Polyvinylidene fluoride

• UHMW PE / Ultra-high-molecular-weight polyethylene

• 4130

• 4140

• 4340

• 40Cr

• 42CrMo

• 25CrMoV

• Q195

• Q215

• Q235/S235JRC

• 1010

• 1015

• 1018

• 1020

• 1045

• 1060

• 1117

• 12L14

• 12L15

• D2

• A2

• O1

Your Trusted Partner for CNC Machining Services in China

Wherever you are!

We offer a wide range of services: CNC machining, sheet metal fabrication, laser and wire cutting services, also including surface treatment and assembly of parts.

Our facilities meet the highest international standards, using state-of-the-art equipment to deliver quality results at a reasonable cost.

Allied Metal has experienced technicians and a certified QA/QC team, and offers the fastest CNC machining services in China.

Industry

Allied Metal provides CNC machining solutions for quality-conscious companies in a wide range of industries.

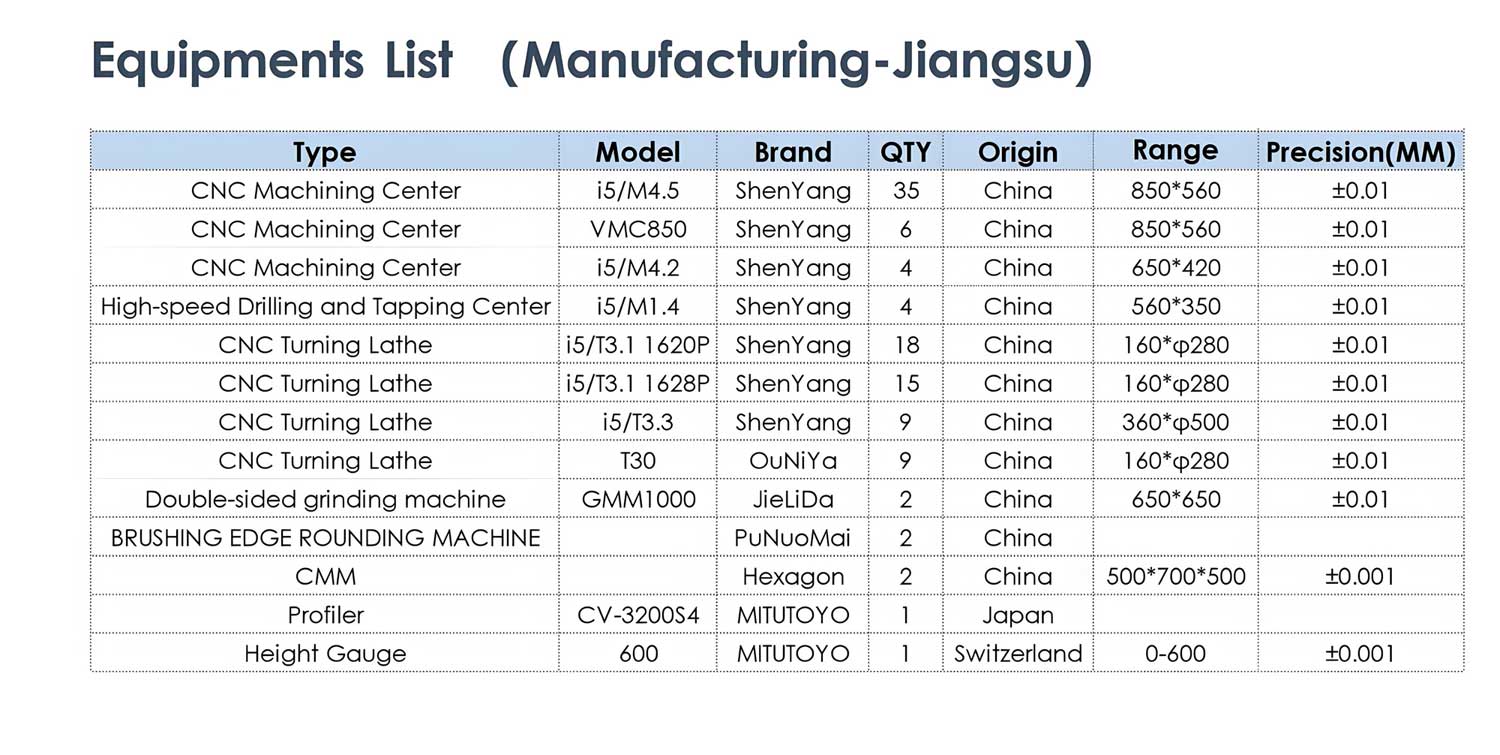

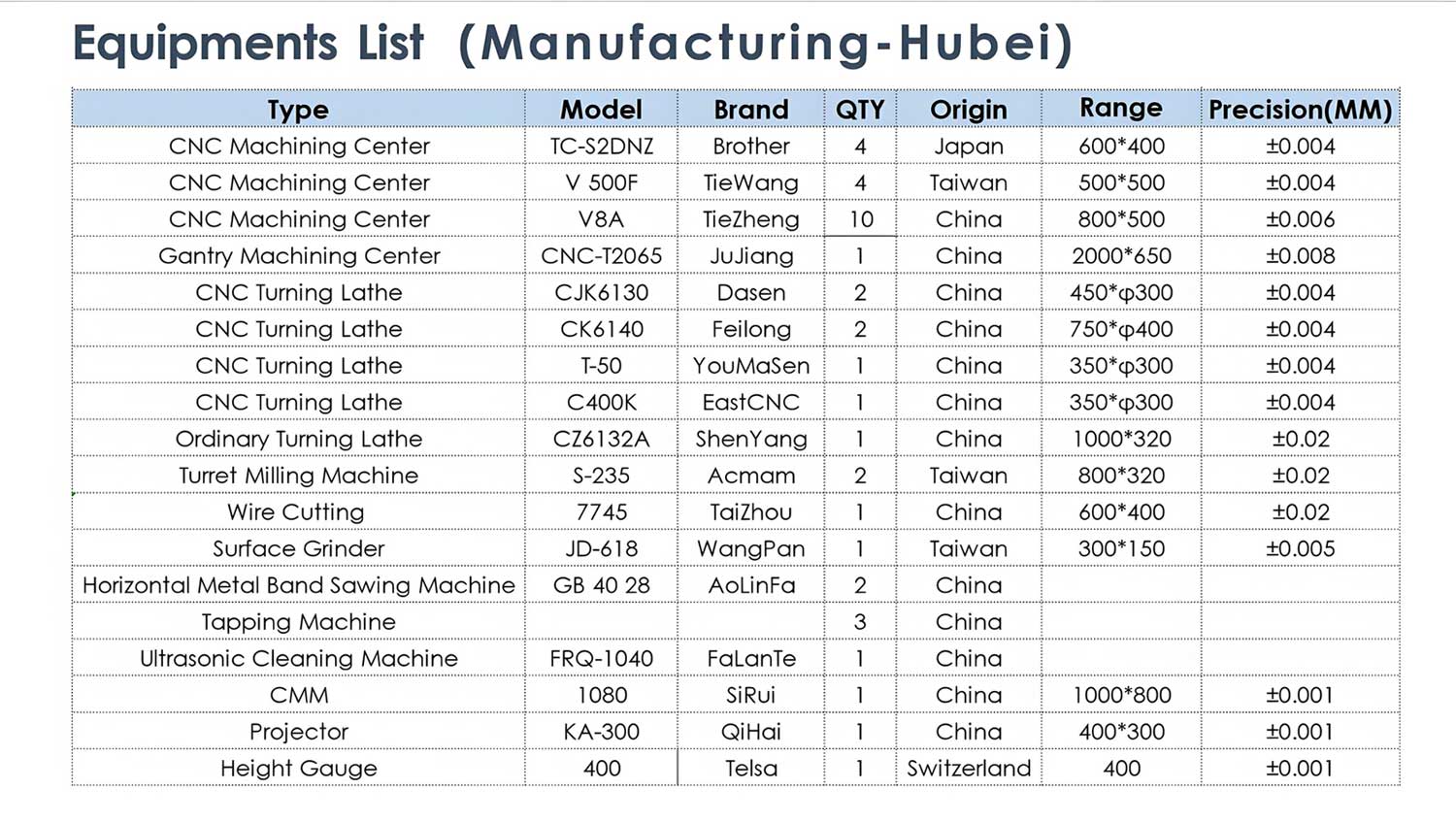

Our processing equipment

Our Certificates:

Our Partners